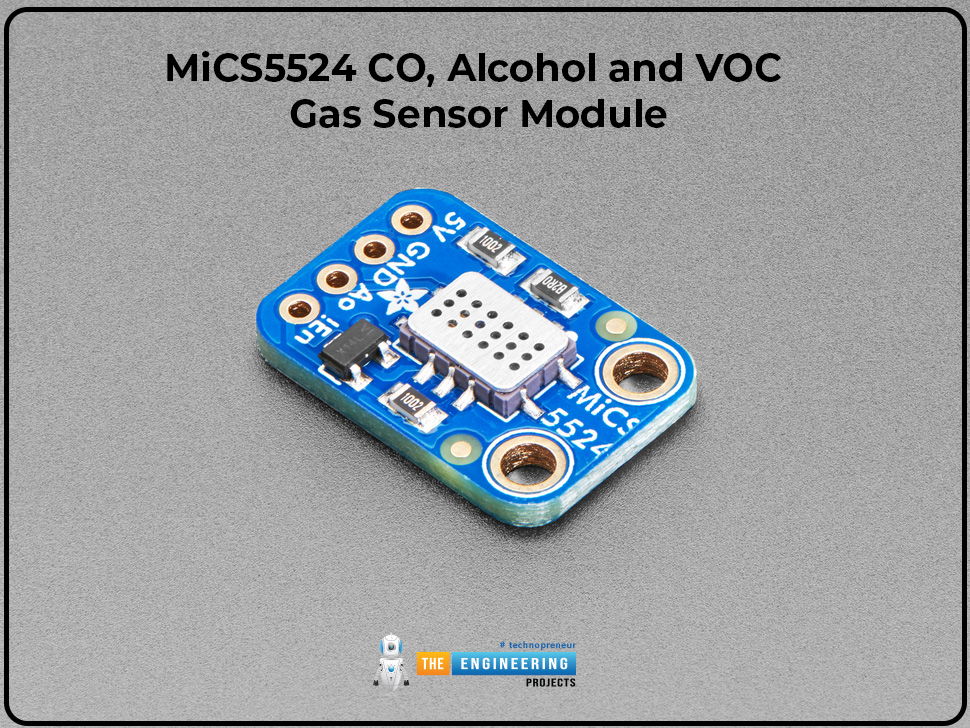

Hi readers! Hopefully, you are well and exploring technology daily. Today, the topic of our discourse is the MiCS5524 CO, Alcohol, and VOC Gas Sensor Module. You might already know about it or something new and different.

MiCS5524 is a multi-gas sensor module designed to detect a wide range of gases, including Carbon Monoxide, Alcohol, and Volatile Organic Compounds. Utilizing Metal Oxide Semiconductor (MOS) technology, this sensor is highly sensitive and reliable in concentration measurements and, thus, very apt for applications in air quality monitoring, industrial safety, environmental protection, and automotive systems.

The MiCS5524 works on the principle of a heated metal oxide layer, which reacts with the target gases. On contact of gas molecules with the sensor, the molecules cause a change in the electrical resistance of the material, which can then be converted into a measurable signal for detection of the concentration of gas present in the environment.

The main characteristics of the MiCS5524 include low power consumption, rapid response time, and tolerance to environmental conditions. Its outputs are analog voltages directly proportional to the gas concentrations, thus making it a good component for integration into microcontrollers or other electronic systems.

This sensor has the purpose of ensuring safety and air quality since it provides real-time information on gas concentration. As such, it has been able to gain popularity among different developers who need reliable means of gas detection in industrial applications.

This article will discover its introduction, features and significations, working and principle, pinouts, datasheet, and applications. Let's dive into the topic.

Introduction:

- Detects a wide range of gases, including Carbon Monoxide (CO), Alcohol, and Volatile Organic Compounds (VOCs).

- It uses MOS technology hence increasing sensitivity and reliability in the concentration measurement of gases.

- Air quality monitoring, industrial safety, and protection environment, and automotive systems.

- This method measures the variation of electrical resistance in a heated metal oxide layer as it responds to target gases.

- Features low power consumption, fast response time, and adaptability to different environmental conditions.

- Provides an analog voltage that is proportional to the concentration of the gas, making it easier to interface with microcontrollers and electronic systems.

- Plays a critical role in improving safety as well as air quality through real-time data on the detection of gases.

Features:

Multi-gas detection:

One of the beautiful characteristics of the MiCS5524 is that it can sense several gases. It is designed for carbon monoxide, alcohol, and volatile organic compounds (VOCs). Thus, it is one of the most versatile sensors which could be applied to various applications.

Carbon Monoxide (CO):

It is a colorless, odorless gas; dangerous at higher concentrations. MiCS5524 provides extremely sensitive and accurate measurements of very low concentrations of CO. In dangerous leaking situations, house safety, and industrial poisoning through CO, real-time monitoring is of utmost importance.

Alcohol:

Alcohol vapors are primarily ethanol in nature. Thus, these are sensed by MiCS5524 and hence highly used for devices intended to measure alcohol in one's breath. It finds extreme usage in enforcement and safety areas as well as the device meant for breathalyzers.

VOCs:

This category of organic compounds is termed by the abbreviation VOCs, health hazardous, in paints, and cleaning agents, among other industrial solvent-based chemicals. This accounts for the importance attached to the functionality of the sensor by MiCS5524 in air quality and industrial security.

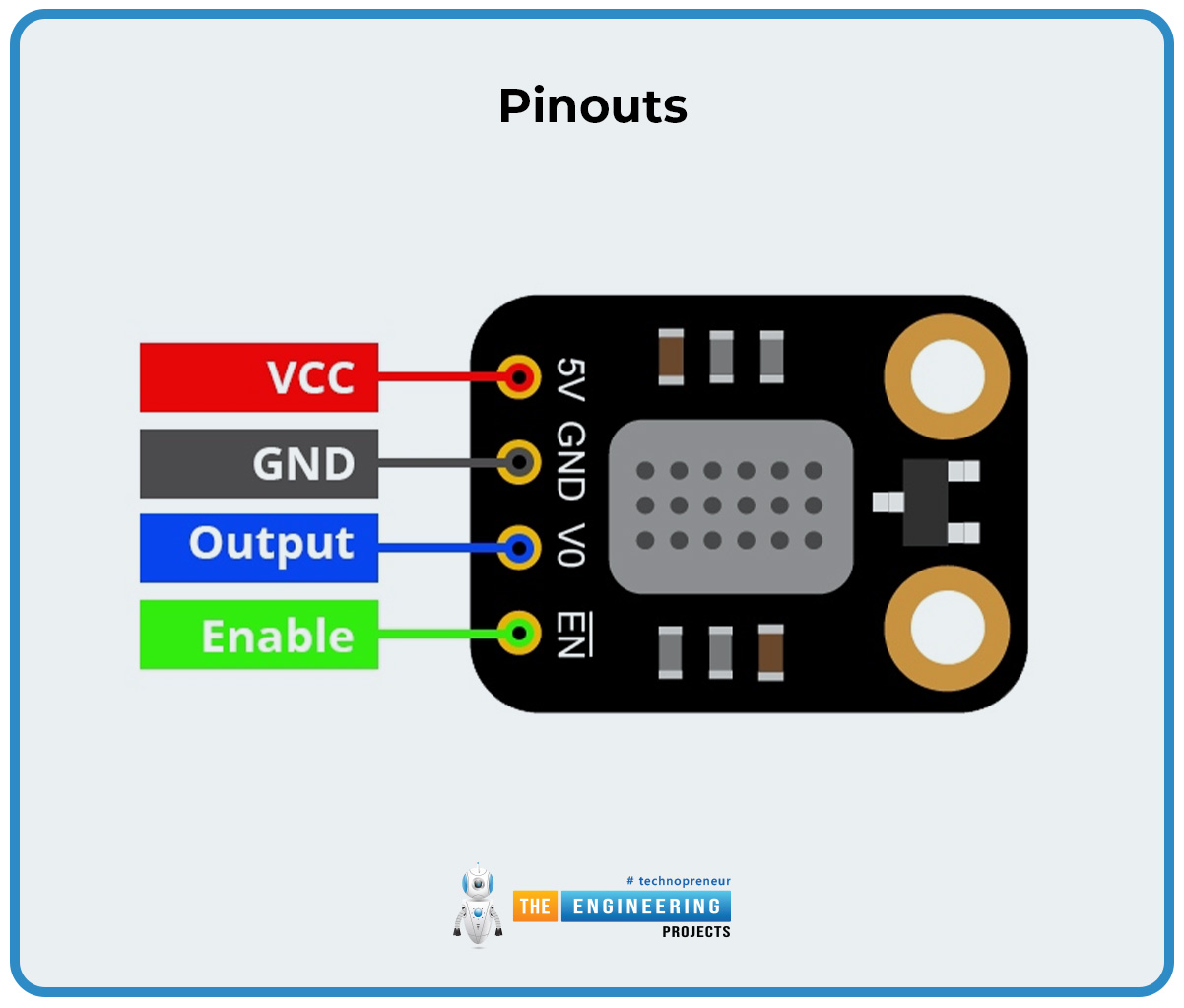

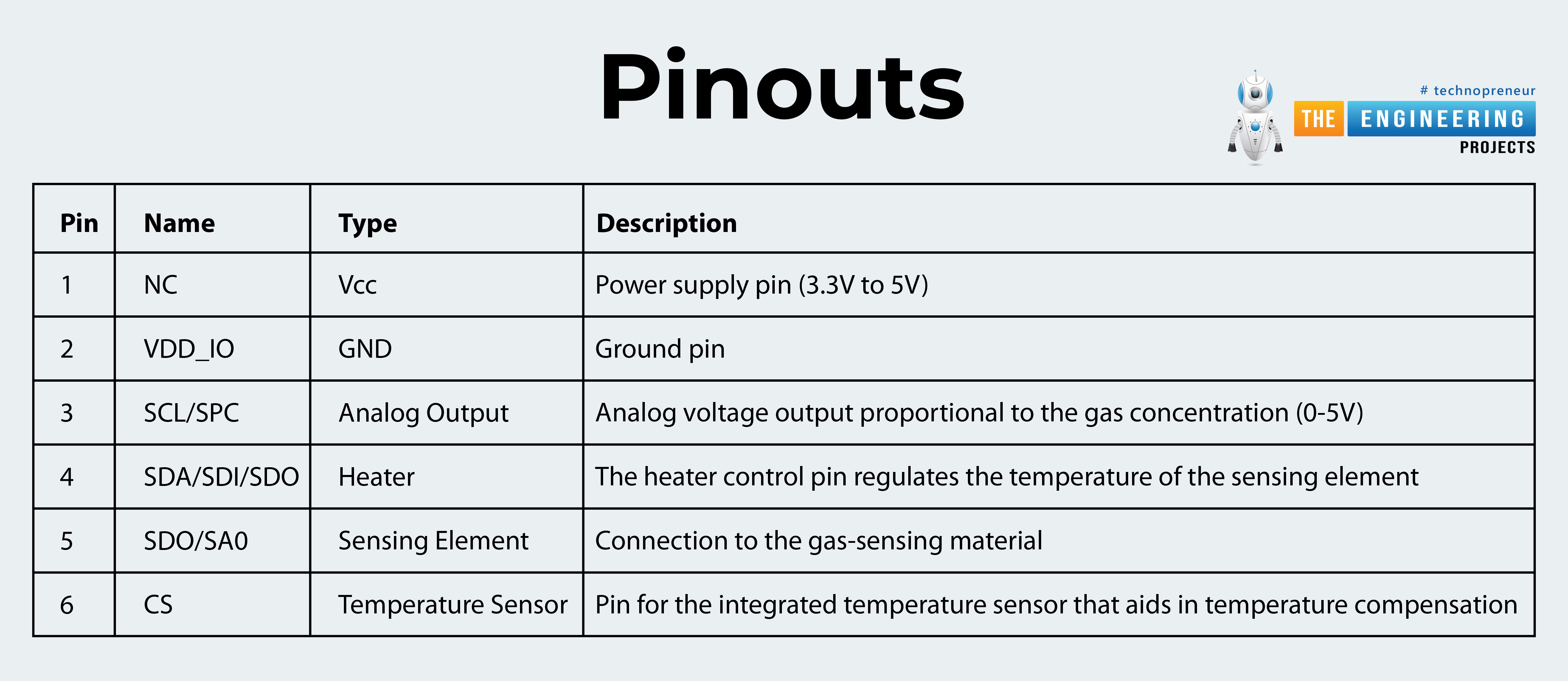

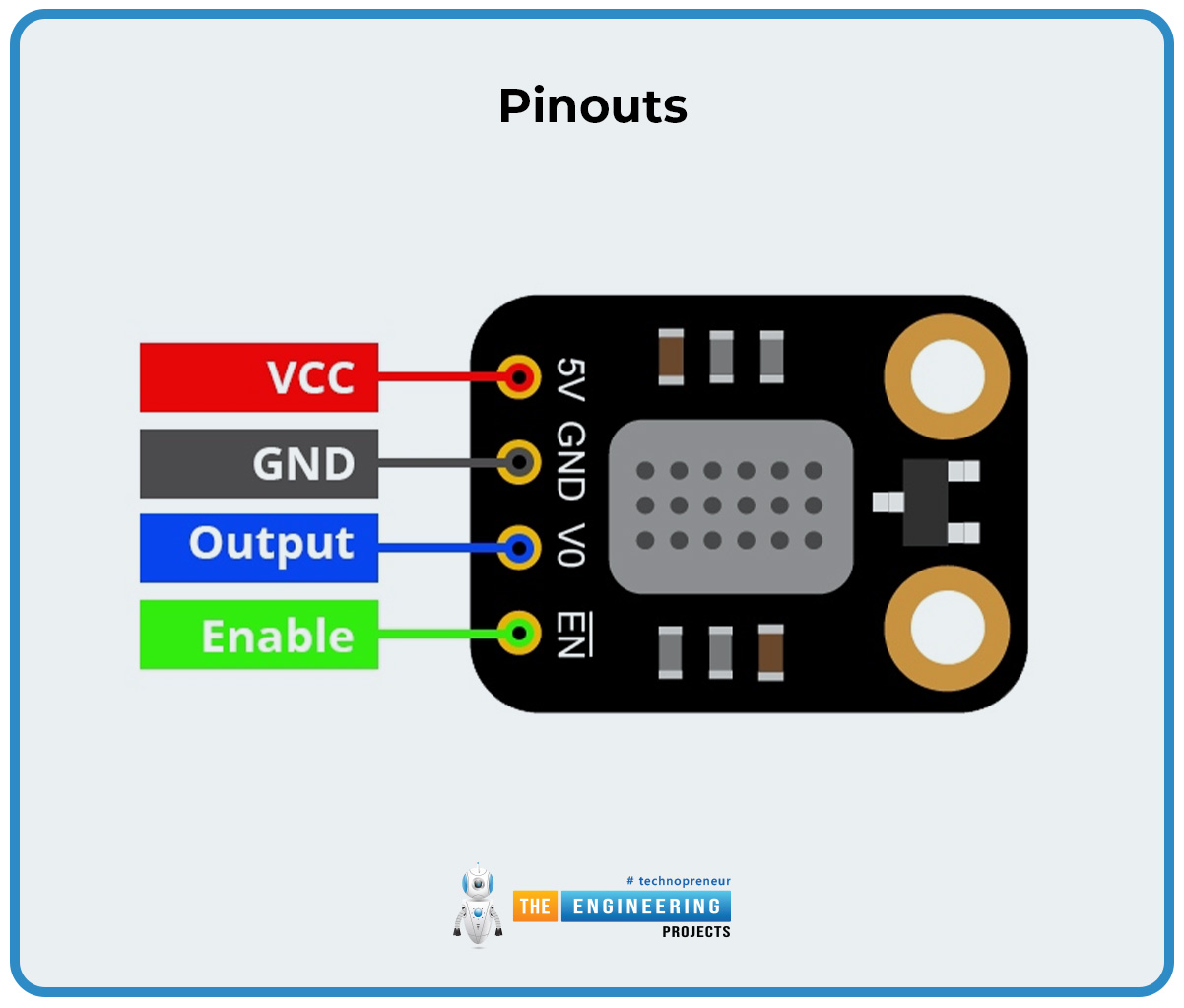

Pinouts:

Pin |

Name |

Description |

1 |

Vcc |

Power supply pin (3.3V to 5V) |

2 |

GND |

Ground pin |

3 |

Analog Output |

Analog voltage output proportional to the gas concentration (0-5V) |

4 |

Heater |

The heater control pin regulates the temperature of the sensing element |

5 |

Sensing Element |

Connection to the gas-sensing material |

6 |

Temperature Sensor |

Pin for the integrated temperature sensor that aids in temperature compensation |

Highly sensitive:

The MiCS5524 is sensitive to gases and delivers reliable, real-time data on gas concentrations. It is efficient for the detection of low concentrations of gases. This feature makes it suitable for a wide range of applications where high sensitivity is critical.

Precise Measurements:

The sensitivity of the sensor is such that trace levels of gases, for example, CO or VOCs, can be detected. This is important in environmental monitoring, personal safety, and industrial applications where small leaks or changes in gas concentration may have a significant impact.

Early Detection:

High sensitivity means that the sensor can detect gases at an early stage before becoming hazardous or a health risk. Such a feature is highly important in safety applications, for example, indoor air quality monitoring and CO detection in a residential setting.

Low Power Consumption:

Another important feature of the MiCS5524 is its low power consumption, which makes it ideal for battery-powered devices and systems requiring long operational lifetimes without frequent recharging or changing of batteries.

Portable Devices Using Low Power Consumption:

Since it consumes very little power, MiCS5524 can be included in portable detection systems for gas used anywhere, from personal alarms and safety devices to wearables. In this way, it has enough time to stay up for long durations without a power drain.

Energy Efficiency:

The second area, low-power capabilities, means that the MiCS5524 can also be used in IoT devices and smart systems because low power is a significant energy consideration. For example, smart air quality monitors or environmental sensing devices can now operate continuously with minimal consumption.

Analog Output:

The MiCS5524 offers an output with an analog value directly related to gas concentrations from the sensor. This output is also important for integrating this sensor with any kind of microcontroller, including the Arduino, Raspberry Pi, and other embedded systems.

Real-Time Data Collection:

With analog output, the sensor is able to send signals in real-time to a microcontroller or an analog-to-digital converter (ADC) for continuous monitoring. The MiCS5524 makes it suitable for applications requiring real-time data collection such as air quality monitoring systems, wearable safety devices, and industrial gas detection systems.

Ease of Integration:

The reason output from the analog signal may be handled easily by simple electronics is that it would simply design and build systems that can sense changes in the gas concentrations. For a DIY project, prototype systems and customized gas detection solutions, that is pretty precious.

Resistance and extremely stable:

The MiCS5524 sensor is designed to provide high stability over time. It will not be less sensitive or accurate even after a long period of usage, making it very suitable for long-term monitoring systems where consistent performance is critical.

Long-Term Reliability:

This allows for great and stable performance over time whether for residential or industrial purposes. In cases where long-duration fluctuation of gas content does occur, the MiCS5524 will provide reliable readings while showing minimal drift and fall in accuracy.

Low Drift:

The drift of most gas sensors is seen to decrease or oscillate over time. MiCS5524 is designed with drift minimized so that measurements will be stable and accurate throughout the sensor's lifetime. This makes it applicable in applications requiring long-term monitoring.

Integral Heater:

The MiCS5524 has an inbuilt heater that will be incorporated into the sensor to enable heating of the sensing material. The heater enables it to ensure that the tin oxide layer within the sensor is at the right temperature for the detection of gases.

Optimized Gas Sensing:

It maintains the gas-sensing material, which is primarily tin oxide, at the appropriate temperature to react with target gas molecules. The heater is required to make the sensor work in the detection of gases, such as CO, alcohol, and VOCs.

Temperature Control:

The integrated heater allows effective temperature and sensing conditions control, thus allowing better sensor performance, especially for the detection of low-concentration gases.

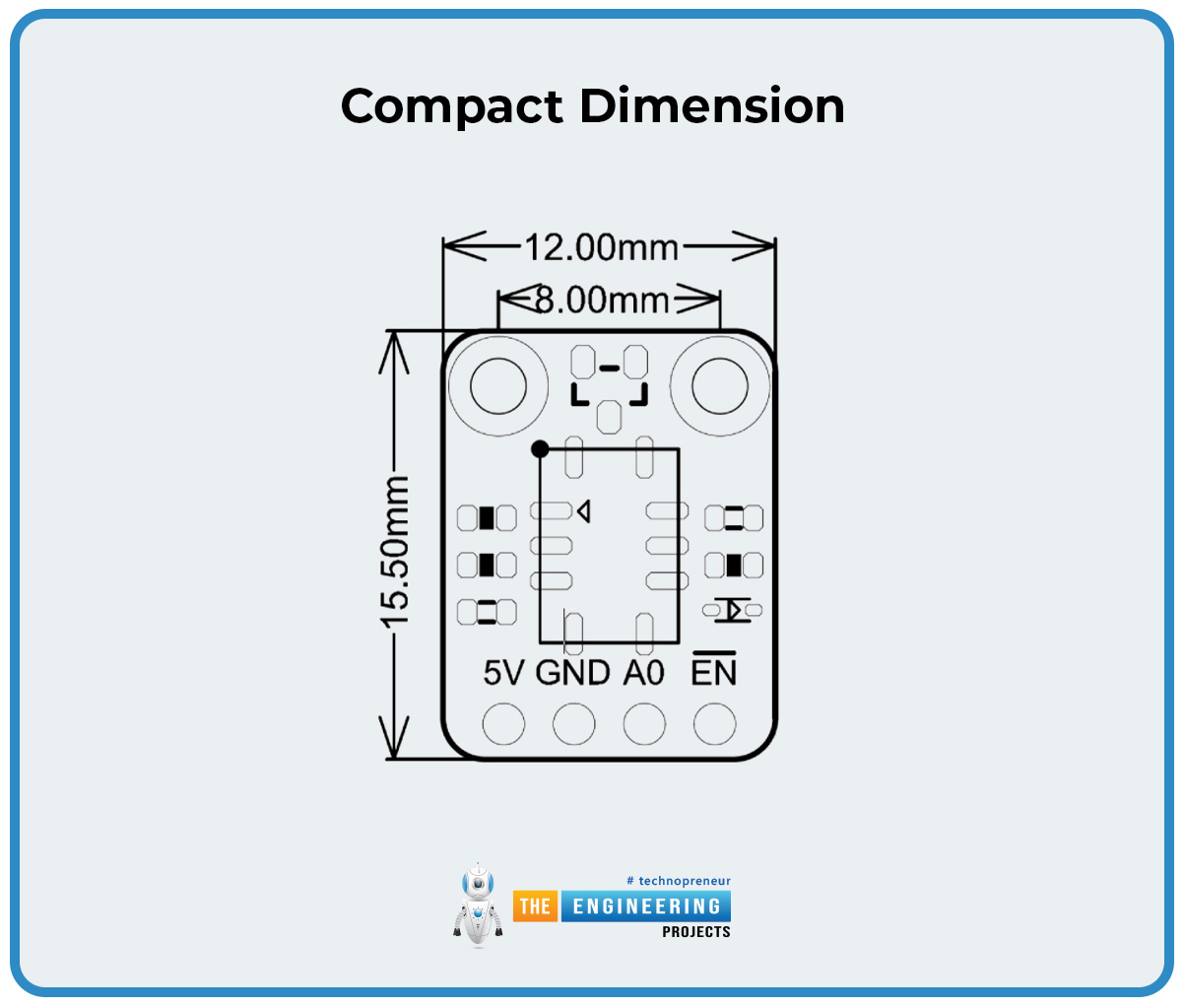

Compact Dimension:

MiCS5524 is manufactured with compact form factors to ensure easy integration in portable and wearable systems as well as fixed installations.

Space-Efficient:

In terms of size, the compactness of the MiCS5524 makes it fit some space-conscious applications. It can thus find its way into a wearable, a small personal gas detector, and small environmental monitoring systems.

Flexible Integration:

Because of the compact nature of the sensor, it can easily be integrated into devices with limited spaces to accommodate, for instance, smartphones, smartwatches, and house automation systems.

Calibration Skills:

The MiCS5524 is designed to be easily calibrated for specific gases so that the sensor provides accurate readings on a wide range of applications.

Easy Calibration:

This permits easy calibration to any gas concentration. Calibration ensures that the sensor output becomes reliable and gives proper data, which is necessary in a great number of applications involving air quality monitoring and safety.

Adjustable Sensitivity:

The sensor sensitivity can be adjusted in such a manner that it responds well to any concentration level of the gases. This makes the users get the best sensor optimization for any need of application.

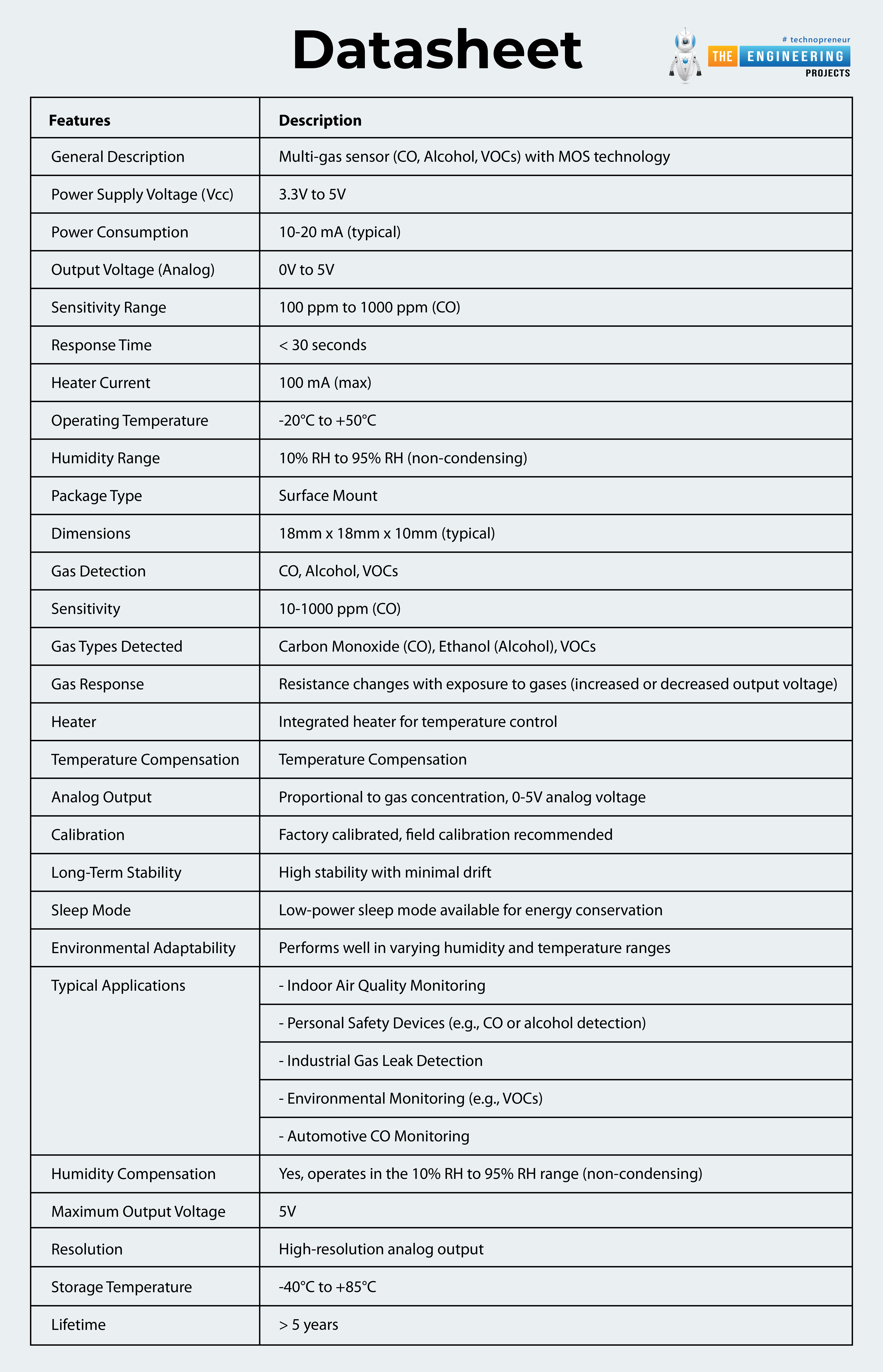

Datasheet:

Features |

Description |

General Description |

Multi-gas sensor (CO, Alcohol, VOCs) with MOS technology |

Power Supply Voltage (Vcc) |

3.3V to 5V |

Power Consumption |

10-20 mA (typical) |

Output Voltage (Analog) |

0V to 5V |

Sensitivity Range |

100 ppm to 1000 ppm (CO) |

Response Time |

< 30 seconds |

Heater Current |

100 mA (max) |

Operating Temperature |

-20°C to +50°C |

Humidity Range |

10% RH to 95% RH (non-condensing) |

Package Type |

Surface Mount |

Dimensions |

18mm x 18mm x 10mm (typical) |

Gas Detection |

CO, Alcohol, VOCs |

Sensitivity |

10-1000 ppm (CO) |

Gas Types Detected |

Carbon Monoxide (CO), Ethanol (Alcohol), VOCs |

Gas Response |

Resistance changes with exposure to gases (increased or decreased output voltage) |

Heater |

Integrated heater for temperature control |

Temperature Compensation |

Temperature Compensation |

Analog Output |

Proportional to gas concentration, 0-5V analog voltage |

Calibration |

Factory calibrated, field calibration recommended |

Long-Term Stability |

High stability with minimal drift |

Sleep Mode |

Low-power sleep mode available for energy conservation |

Environmental Adaptability |

Performs well in varying humidity and temperature ranges |

Typical Applications |

- Indoor Air Quality Monitoring |

- Personal Safety Devices (e.g., CO or alcohol detection) |

|

- Industrial Gas Leak Detection |

|

- Environmental Monitoring (e.g., VOCs) |

|

- Automotive CO Monitoring |

|

Humidity Compensation |

Yes, operates in the 10% RH to 95% RH range (non-condensing) |

Maximum Output Voltage |

5V |

Resolution |

High-resolution analog output |

Storage Temperature |

-40°C to +85°C |

Lifetime |

> 5 years |

Gas Detection Sensitivity Table:

Gas |

Sensitivity range |

Carbon Monoxide (CO) |

10-1000 ppm |

Alcohol (Ethanol) |

50-1000 ppm |

Volatile Organic Compounds (VOCs) |

Detects a wide range of VOCs including methane, propane, formaldehyde, etc. |

Working Principle:

Sensing element: Metal Oxide Semiconductor (MOS):

The core technology of MiCS5524 features an element made from metal-oxide thin film material: tin oxide (SnO₂) is very typically the material. Such metal oxide film is highly sensitive to a lot of gases. This simple basic working principle boils down to a change of electric resistance by the material as it gets exposed to its target gases. This interaction causes a reaction at the surface of the metal oxide material, which creates an electrical conductivity change that can be measured to extract the concentration of the gas.

Surface Reaction and Absorption of Gases:

When the metal oxide material comes into contact with the target gas, say CO, alcohol, or VOC, then gas molecules start adsorbing on the metal oxide material's surface. Depending upon the type of gas and conditions in which it occurs, several reactions take place:

Oxidizing Gases (e.g., CO, Alcohol):

Oxidizing gases- for example, CO, the gas molecules donate electrons to the metal oxide surface, thus reducing the electron concentration at the material surface. This results in an increase in resistance.

Reducing Gases (e.g. VOCs):

The gas molecule accepts electrons from the oxide surface of the metal. The concentration of electrons develops a charge on the surface. Hence, it decreases the resistivity. The variation in resistance caused by the interaction between the gas and the metal oxide surface is what the MiCS5524 uses to measure the gas concentration.

Heater Element for the Temperature Control:

The MiCS5524 sensor module has an integrated heater element that is crucial for controlling the temperature of the sensing material. The heater ensures that the tin oxide layer reaches an optimal temperature for gas sensing. This is important because the reactivity of the metal oxide material to gases is temperature-dependent. By keeping the temperature stable and constant, the heater ensures that the sensor gives reliable and precise results, thus avoiding changing readings due to environmental temperature changes.

The heater provides a controlled heat source to the sensing element. This allows the sensor to heat up while it facilitates the reaction between the gas molecules and the metal oxide material, thereby enhancing the detection process. This is very important for making sure that even low concentrations of gases can be detected precisely and that the sensor works with high sensitivity.

Gas Sensitivity and Selectivity:

The MiCS5524 sensor is highly sensitive to certain gases, such as CO, alcohol, and VOCs. Selectivity is the ability of the sensor to distinguish between different gases. This selectivity may be affected by temperature, concentration of the gas, and humidity.

Carbon Monoxide (CO):

The sensor is highly sensitive to CO because it reacts with the metal oxide layer and changes its conductivity. Detection of CO is very critical, especially in environments like gas leak sensing and automotive systems, where exposure to this gas is dangerous and even lethal to human life.

Ethanol:

The MiCS5524 can sense alcohol vapors, especially ethanol which is a frequently used alcohol within a breathalyzer. The reaction of ethanol gas to the sensor changes its resistance, and this can be calculated to be used as an approximation of ethanol concentration.

VOCs:

VOCs are an organic group of chemicals emitted from products such as paints, solvents, and cleaning agents. MiCS5524 detects VOCs with the same principle of resistance change, making them a very useful tool for indoor air-quality monitoring systems for industrial and commercial purposes.

Applications:

Automotive Safety:

Detects CO levels in vehicles ensuring the safety of drivers from noxious gases that may concentrate in enclosed spaces.

Gas Leak Detection:

Applied in industrial settings and laboratory settings for detection purposes, especially CO and other VOC, in which early warnings may reduce hazardous situations.

Environmental Monitoring:

It is applied in a system of environmental monitoring due to the prevalence of its existence in pollution or any urban setting.

Indoor Air Quality Monitoring:

The equipment detects harmful gases in a house, office, or business and determines whether the air is within the safe limits to allow safe indoor breathing.

Personal Safety Devices:

It is integrated with wearable portable devices like safety monitors which can detect alcohol or ethanol levels and carbon monoxide levels in workplaces, houses, or vehicles.

Conclusion:

The MiCS5524 gas sensor module is a powerful, flexible, and cost-effective solution that can be used to detect carbon monoxide, alcohol, and volatile organic compounds among others. Due to the ability of this module to provide measurements accurate and reliable, low power consumption, and high sensitivity, the module is suitable for several applications, such as air quality monitoring, personal safety, and industrial monitoring.

This sensor uses MOS technology with a tin oxide sensing material and an integrated heating element. Its analog output can easily be incorporated into microcontroller-based systems, thus allowing for real-time data collection and analysis. It is compact, stable in the long term, and easy to calibrate, making it useful in many industries and everyday applications.

As gas detection continues to play a central role in ensuring safety and environmental protection, it remains a very relevant solution for gas sensing technology. The MiCS5524 provides an effective, reliable method of monitoring dangerous gases in real time either in smart home devices or wearables, as well as in industrial safety systems.