Engineering change management is vital for managing changes in product design and ensuring smooth development and production. It helps prevent costly errors and maintains product quality. This article will guide you through essential processes, tools, and best practices for effective engineering change management.

Effective engineering change management involves systematic evaluation, approval, and implementation to minimize disruptions and enhance product quality.

Key steps in the change management process include identifying change needs, detailed documentation, comprehensive evaluation, and seamless implementation.

Tools like Product Lifecycle Management (PLM) and OpenBOM streamline change management processes, improving collaboration, traceability, and overall efficiency.

Understanding Engineering Change Management

Engineering change management software controls changes to product information throughout product development, manufacturing, and support. Inefficient change management can lead to chaos and inefficiencies. Rapid, unmanaged changes result in errors, rework, and project delays, which are costly and time-consuming.

Engineering change management processes ensure changes are systematically evaluated, approved, and implemented, minimizing disruptions and maximizing product quality. Structured processes provide traceability and control, keeping all stakeholders informed and aligned. Effective change management enhances collaboration and communication, leading to better decision-making and improved outcomes within the engineering change management workflow.

Product lifecycle management (PLM) systems enhance workflows and improve collaboration between engineering teams, addressing the complexity of modern product development and rising customer demands. Integrating various tools and techniques, PLM systems manage changes efficiently, from initial requests to final implementation.

This holistic approach to change management is essential for maintaining product quality and achieving continuous improvement.

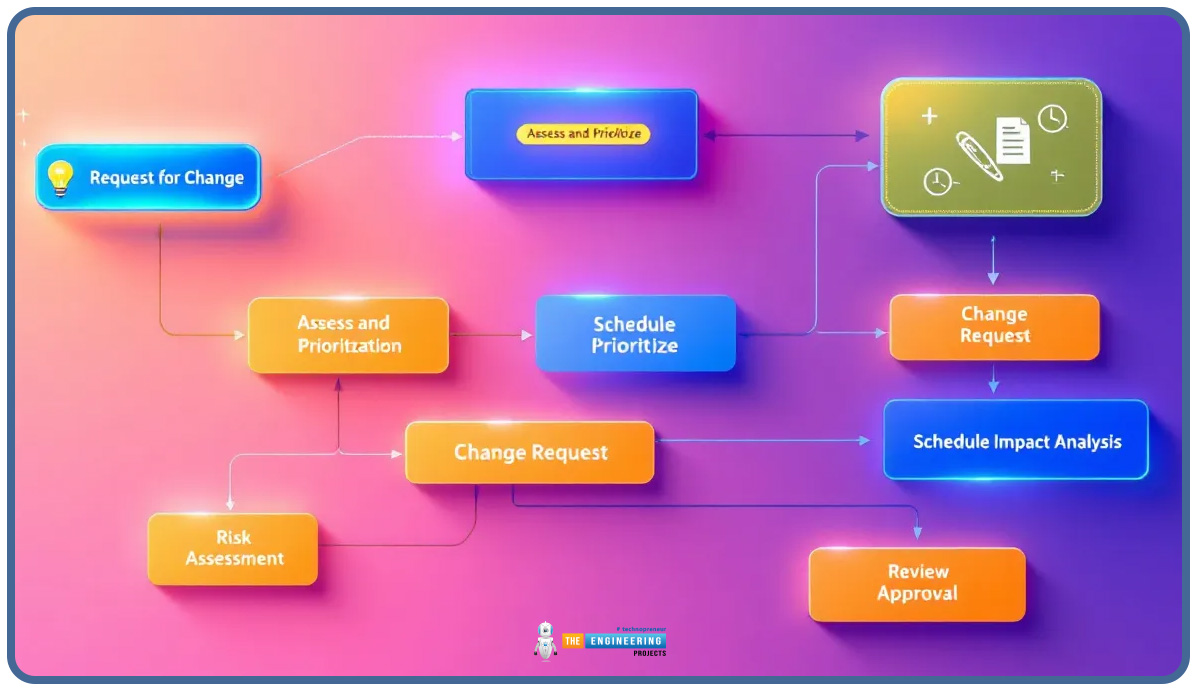

The Engineering Change Management Process

The engineering change management process includes several stages to ensure changes are implemented smoothly and effectively. Identifying change needs, documenting, evaluating, and implementing approved changes are vital steps for maintaining control, ensuring quality, and achieving continuous improvement.

Agility, accurate communication, and stakeholder engagement are central to this process. A systematic approach ensures changes are necessary, feasible, and beneficial.

The final stage of the process involves implementing the best solution, ensuring that all necessary updates are made and that the change is integrated seamlessly into the product design or manufacturing process.

Identifying Change Needs

Identifying the need for change is the first step in the process. Various stakeholders, including employees and customers, can report problems or opportunities for change. This phase involves thorough analysis to identify the root cause and the objects needing modification. Detailed investigations help engineering teams pinpoint exact changes needed in design, parts, or documents.

The process begins with an engineering change request (ECR), triggering a review and analysis by a designated team. This initial step sets the stage for all subsequent actions. Identifying the root cause through investigation and analysis ensures proposed changes address actual problems and lead to meaningful improvements.

Documenting Changes

Detailed documentation is the backbone of effective change management. It captures the rationale, anticipated impacts, and technical specifications of proposed changes. Comprehensive documentation details the proposed change, its rationale, and potential impacts on cost, time, resources, quality, and expected benefits, ensuring all stakeholders understand the change and its implications.

Lack of detailed documentation can lead to misunderstandings, project delays, and unintended consequences. Thus, documenting every aspect of the proposed change, including technical specifications, impact analysis, risk assessments, cost implications, and schedules, ensures all relevant information is available for informed decision-making and smooth implementation.

Evaluating and Approving Changes

The evaluation phase involves assessing risks, technical feasibility, and potential impacts of proposed changes on existing systems. A cross-functional team evaluates product performance, cost implications, manufacturing feasibility, and effects on other parts, ensuring all potential risks and impacts are considered before making a decision.

Engineers and stakeholders analyze change request documentation to support informed decision-making. Thorough risk analysis and feasibility evaluation help the team make decisions that minimize risks and avoid costly errors.

This phase is essential for gaining formal approval, ensuring that only beneficial and feasible changes are implemented.

Implementing Approved Changes

Implementing approved changes requires a quick and efficient response to minimize disruption. This phase uses common procedures like approval processes to integrate the change into product design or manufacturing. Necessary documents, such as specifications and technical drawings, must be updated to reflect changes accurately.

Coordination among departments is crucial, especially in advanced stages of product development. Ensuring all relevant teams are aligned and informed allows for smooth and effective implementation of changes, which is often the responsibility of a project manager.

This final stage of the engineering change management process ensures that the best solutions are integrated seamlessly into the product, maintaining quality and meeting customer demands.

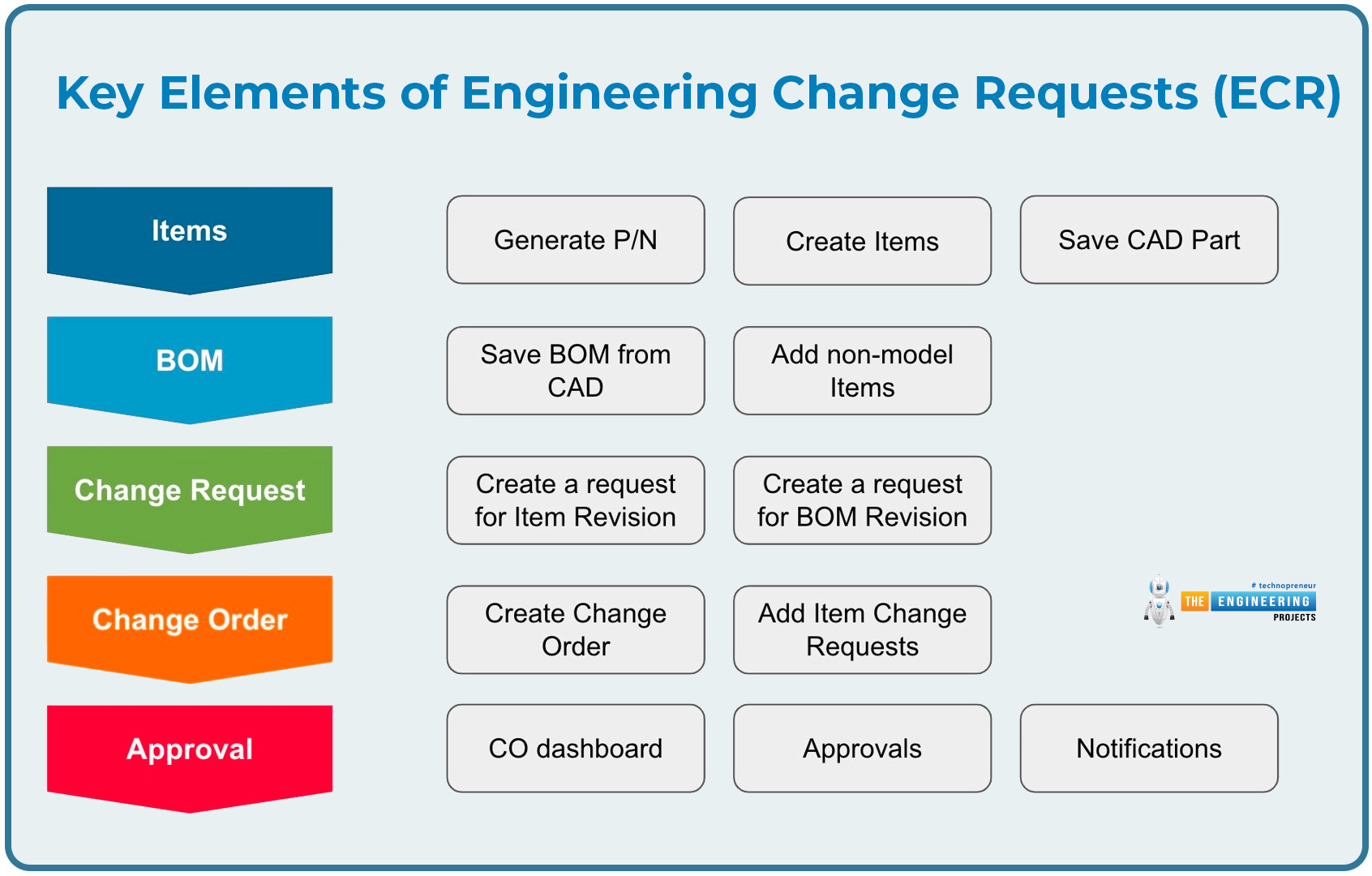

Key Elements of Engineering Change Requests (ECR)

An engineering change request (ECR) is a formal request submitted by stakeholders to propose changes for improvements or to address problems. An ECR details the changes needed, providing a clear rationale and outlining potential impacts. ECRs maintain product quality, ensure compliance, and facilitate continuous improvement in manufacturing, including engineering change notifications and engineering change notices.

A well-structured ECR serves as a communication tool, outlining the proposed change, its rationale, potential impacts, and necessary approvals. It typically includes a description of the encountered problem, reasons for the change, affected parts, and stakeholders involved.

Providing all necessary information, ECRs enable decision-makers to evaluate the justification for the change and plan its implementation effectively. This structured approach maintains control over the change management process and ensures successful outcomes.

Tools and Techniques for Effective Change Management

Effective change management relies on various tools and techniques to streamline the process and ensure accuracy. Integrating Engineering Change Management (ECM) into the enterprise-wide digital thread drives productivity and overall value. Product Data Management (PDM) and Product Lifecycle Management (PLM) systems control changes during implementation, connecting sign-offs, markups, and comments to product data with audit trails, enhancing traceability and accountability.

Automatic synchronization of resolved changes with manufacturing systems ensures updates are accurately reflected. Accurate, fast-paced, and coordinated processes, along with automated change management and configurable change process, create a streamlined change environment.

Tools like OpenBOM enable the creation of change orders that consolidate multiple change requests for streamlined approval, further enhancing efficiency.

Product Lifecycle Management (PLM) Systems

Product Lifecycle Management (PLM) systems enhance workflows by integrating various processes and improving team collaboration. These systems ensure everyone is on the same page, facilitating seamless communication and coordination. Connecting PDM and PLM processes helps companies improve product quality and reduce costs.

Automated approvals for ECR and ECO processes within PLM systems facilitate collaboration on change requests. This integration helps maintain product quality and ensures efficient change management throughout the product lifecycle.

PLM systems are indispensable for modern engineering teams, providing the tools to manage complex change processes effectively.

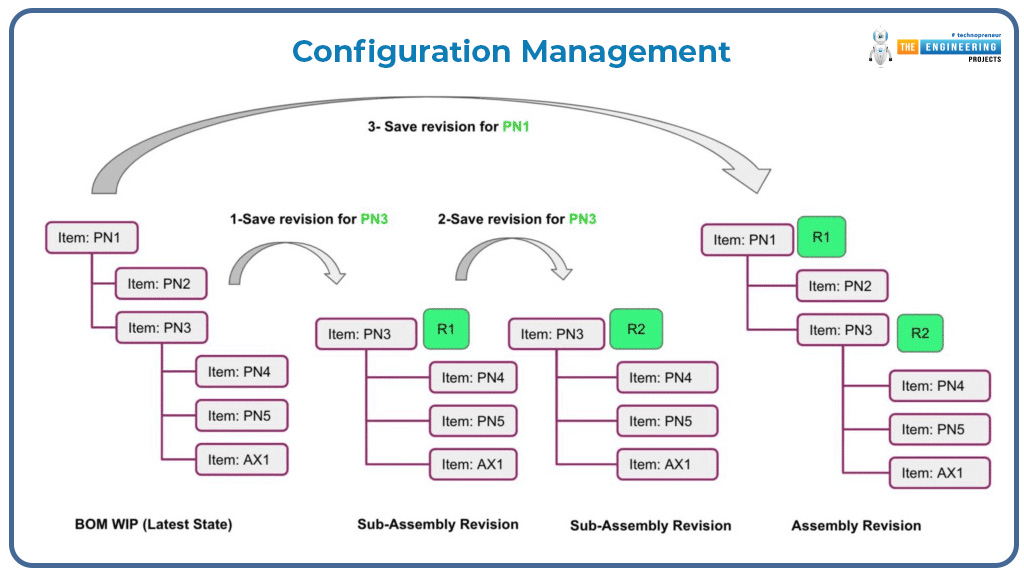

Configuration Management

Configuration management maintains accurate product history, ensuring stakeholders work with correct product information. PLM systems integrate workflows and enhance collaboration around product data management. OpenBOM simplifies tracking product lifecycle changes, maintains change history, and supports revisions and approvals effectively.

With OpenBOM, users can view and manage change history and item/BOM revisions, providing a clear and accurate record of all changes. This capability ensures highly configured products can be tracked and managed accurately throughout their lifecycle.

Effective configuration management combined with advanced tools like OpenBOM ensures streamlined and efficient change management processes.

Automated Workflows

Automating change processes streamlines the management of product revisions, ensuring changes are handled efficiently. Automation improves efficiency by reducing time spent on manual tracking and documentation. OpenBOM automates change tracking, ensuring seamless management of product revisions.

Automating these processes allows teams to focus on innovation rather than repetitive manual tasks. This shift enhances productivity and ensures changes are implemented with minimal disruption to operations.

Automated workflows are a game-changer for modern engineering teams, providing tools to manage change processes effectively and efficiently.

Best Practices for Engineering Change Management

Embracing best practices in engineering change management ensures seamless operations and successful outcomes. Clear procedures should outline the steps for proposing, evaluating, approving, and implementing changes. These procedures should involve all relevant stakeholders, define their roles and responsibilities, and ensure a smooth workflow for change requests.

Communication is vital in the change management process, ensuring all relevant stakeholders are informed about changes and their impacts. A well-structured change control board can facilitate the review and prioritization of change requests from diverse stakeholders.

Thorough documentation is crucial for tracking change requests, approvals, implementation details, test results, and outcomes. By following these best practices, companies can avoid pitfalls like increased costs, delays, and reduced customer feedback satisfaction.

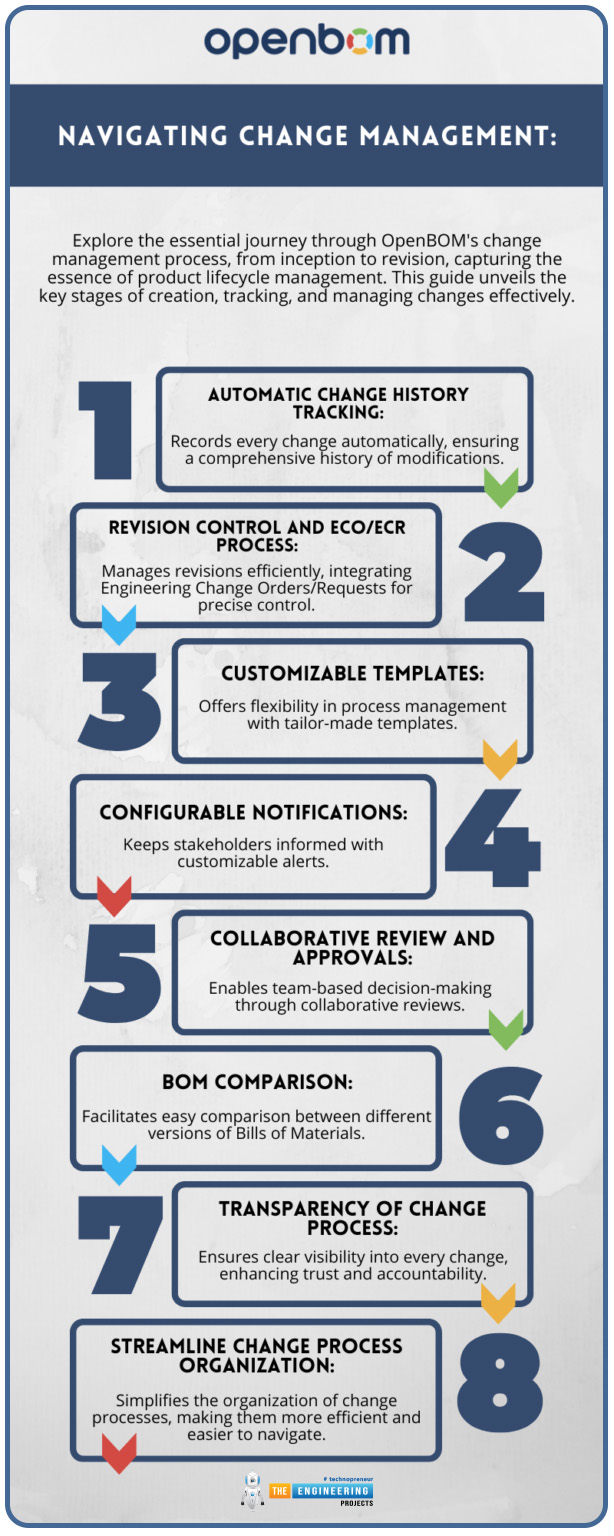

How OpenBOM Facilitates Change Management

OpenBOM simplifies change management by providing a comprehensive platform to track the product lifecycle and manage changes effectively. It allows users to view change history, revisions, change reports, change requests, and approvals, ensuring all changes are captured and preserved in the OpenBOM database. This capability maintains control over the change management process and ensures all stakeholders are informed and aligned.

By capturing changes in catalogs, Bill of Materials (BOMs), orders, and more, OpenBOM ensures all relevant information is available for informed decision-making. This holistic approach simplifies tracking changes and supports effective management of engineering change orders and requests.

OpenBOM’s advanced features make it indispensable for modern engineering teams, providing the efficiency and traceability needed for successful change management.

Change History and Revisions

OpenBOM allows users to create item revisions, unchangeable snapshots of item data. These revisions maintain an accurate record of all changes, ensuring stakeholders have access to up-to-date information. Users can generate reports detailing changes in a BOM between different revisions, facilitating easy identification of changes.

OpenBOM enables side-by-side comparisons of different revisions, making it easy to track and manage changes. This feature helps identify discrepancies and ensures all changes are accurately documented.

Providing a clear view of change history and revisions, OpenBOM supports effective change management and enhances collaboration among engineering teams.

Change Requests and Orders

OpenBOM’s advanced change management mechanism supports the management of engineering change orders and change request approvals. The “Sign-Off” dashboard in OpenBOM allows everyone involved in the approval process to see the current status and make their approvals in a single, collaborative dashboard that is always up to date. This feature streamlines the approval process, ensuring that all stakeholders are informed and aligned.

When the “Change Management” mechanism is enabled in OpenBOM, the “Change Request” command replaces the “Save Revision” command, initiating the change approval process. This mechanism provides three levels of change management: change history, item and BOM revisions, and change requests and orders.

By supporting these advanced features, OpenBOM ensures that all changes are managed efficiently and effectively, providing the tools needed for successful change implementation.

Summary

Effective engineering change management is crucial for maintaining product quality, meeting customer demands, and ensuring smooth operations. By following a structured process that includes identifying change needs, documenting changes, evaluating and approving changes, and implementing approved changes, organizations can manage changes efficiently. Tools like OpenBOM facilitate these processes, providing comprehensive features for tracking changes, managing revisions, and streamlining approvals. Embracing best practices and utilizing advanced tools ensures successful change management and continuous improvement.

Frequently Asked Questions

What is the purpose of engineering change management?

The purpose of engineering change management is to effectively control changes to product information throughout all stages of development, manufacturing, and support, ensuring quality and compliance. This process is essential for maintaining consistency and traceability in engineering projects.

Why is change management important in manufacturing?

Change management is crucial in manufacturing as it ensures systematic control over changes, maintaining traceability and preventing disruptions in product development. This structured approach ultimately leads to more efficient operations and improved product quality.

How does OpenBOM facilitate change management?

OpenBOM effectively facilitates change management by providing a comprehensive view of change history, revisions, and approvals, ensuring that all changes are captured and preserved within its database, which enhances transparency and accountability in the process.

What are the three levels of change management mechanisms in OpenBOM?

The three levels of change management mechanisms in OpenBOM are change history, item and BOM revisions, and change requests and orders. These mechanisms collectively ensure systematic tracking and control of changes within your processes.

What does the “Sign-Off” dashboard in OpenBOM do?

The “Sign-Off” dashboard in OpenBOM streamlines the approval process by providing a real-time, collaborative view of statuses, enabling all participants to efficiently manage and complete their approvals in one place.