Choosing between 3D printing and CNC machining can be pivotal for manufacturers, designers, and engineers. Each method has distinct advantages, depending on factors like production volume, material requirements, and the complexity of the design. 3D printing offers unparalleled flexibility. It allows for rapid prototyping and intricate geometries that are difficult to achieve with traditional methods.

On the other hand, custom CNC machining is known for its precision and ability to work with a wide range of materials, making it ideal for producing high-quality parts with tight tolerances. Understanding these differences is crucial for selecting the right technique for your project, whether looking to innovate quickly or produce durable, high-quality components.

This article will look at the key aspects of 3D printing and CNC machining. It will help you determine which method best suits your needs.

What Is 3D Printing?

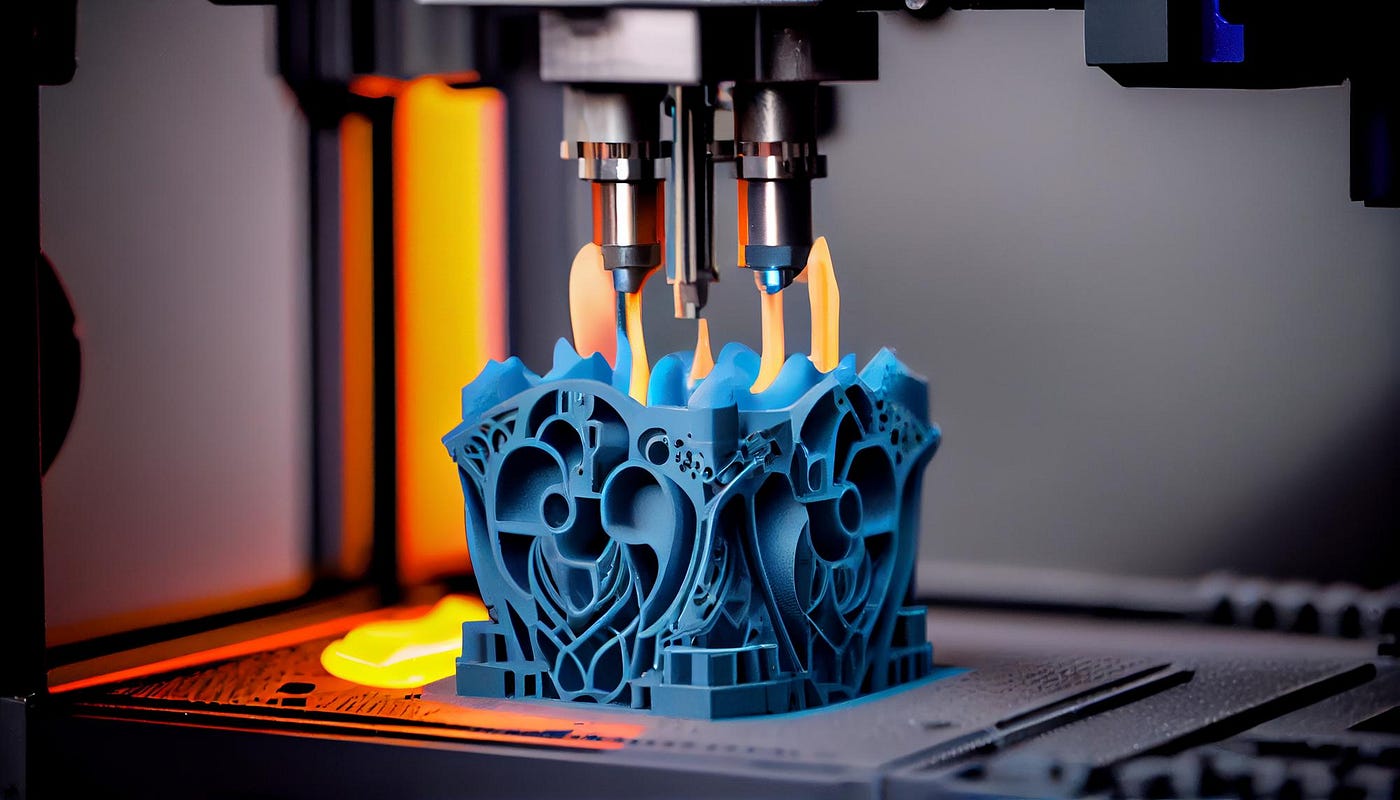

3D printing, or additive manufacturing, is a cutting-edge process to create three-dimensional objects from a digital model. This technique involves building the object layer by layer, which sets it apart from traditional subtractive manufacturing methods that remove material from a larger block. The digital model, typically created using Computer-Aided Design (CAD) software, serves as a blueprint for the object, guiding the printer through each layer's construction.

What Is CNC Machining?

CNC machining, short for Computer Numerical Control machining, is a versatile manufacturing process involving automated machine tool control using computer programs. This subtractive manufacturing technique removes material from a solid block or workpiece to create a highly precise and accurate finished part.

3D Printing VS. CNC Machining: Key Differences

Below are some of the key differences between 3D printing and CNC machining:

Part Design

3D printing offers nearly limitless design flexibility, allowing for the creation of complex geometries and intricate details that would be difficult or impossible to achieve with traditional manufacturing methods. This freedom is due to the addictive nature of the process, which builds parts layer by layer without the need for specific tooling or support for internal features. As a result, designers can focus on optimizing the functionality and aesthetics of the part without being constrained by the manufacturing process itself.

On the other hand, CNC machining is limited by certain design constraints inherent to the subtractive process. These constraints include tool access, tool path, and the need to avoid undercuts and internal geometries that are difficult to reach with cutting tools. Additionally, CNC machining requires careful planning of tool paths. It may also involve multiple setups and repositioning of the workpiece to achieve the desired shape. This method can restrict the complexity of parts that can be efficiently produced.

Precision

The precision of 3D printing varies depending on the specific technology used. Generally, the resolution can range from 0.016 mm to over 1 mm, with typical consumer-grade 3D printers achieving around 0.2 mm precision. While this is sufficient for many applications, achieving high precision consistently across different geometries and materials can be challenging.

CNC machining produces parts with high precision and tight tolerances. It can achieve precision levels as fine as 0.005 mm by employing slow feeds, new cutters, and shallow cuts. This makes CNC machining ideal for applications with critical dimensional accuracy and surface finish, such as aerospace and medical device manufacturing.

Operator Skill

Operating a 3D printer generally requires less specialized skill compared to CNC machining. The process involves preparing a digital file, selecting orientation, and adding necessary support. Once the setup is complete, the printer performs the build with minimal human intervention, making it accessible to users with basic technical knowledge.

CNC machining demands a higher level of operator skill due to the complexity of setting up the machine, programming tool paths, and selecting appropriate cutting tools. Operators need to have a deep understanding of the machining process, material properties, and the capabilities of the equipment to consistently produce high-quality parts. This expertise is critical for achieving the desired precision and surface finish.

Speed of Build

3D printing typically has a low setup time, but the actual build time can be lengthy. It often takes several hours or even days to complete, depending on the size and complexity of the part. This makes it suitable for prototyping and low-volume production, where quick iteration and design flexibility are prioritized.

CNC machining can have high setup and programming times, particularly for complex parts. However, once the setup is complete, the cutting stages are very fast, allowing for rapid part production. This makes CNC machining well-suited for high-volume production runs where speed and efficiency are essential.

Surface Finish

The surface finish of 3D-printed parts can vary widely based on the technology used. Common issues include graininess, rough textures, and visible layer lines. Post-processing methods such as sanding, polishing, and media blasting can improve the finish. However, achieving a smooth, high-quality surface can be challenging without additional work.

CNC machining can produce excellent surface-quality parts, particularly when using longer cut times and finer cutting tools. The process can achieve a highly uniform and precise finish, making it ideal for applications where aesthetic and functional surface properties are important. Various post-processing techniques, such as anodizing and powder coating, can further enhance the surface finish of machined parts.

Strength

The strength of 3D-printed parts is often lower than that of their machined counterparts. Depending on the printing process and material, the strength can range from 10% to 20% of the native material's properties. This is due to the layer-by-layer construction, which can introduce weaknesses and inconsistencies in the final part.

CNC machining produces parts with the full strength of the native material, as the process involves removing material from a solid block. It results in parts with superior mechanical properties and durability, making CNC machining the preferred choice for applications where strength and reliability are critical.

3D Printing Vs. CNC Machining: Which Is Better?

Choosing between 3D printing and CNC machining is influenced by your specific needs. 3D printing is ideal for rapid prototyping, complex geometries, and low-volume production with diverse material options like plastics and metals. It offers customization and reduced waste but may require post-processing for a smooth finish.

CNC machining excels in high precision, consistency, and the ability to work with a wide range of materials, including metals and composites. It's best for producing parts with tight tolerances and in larger volumes. Ultimately, the choice depends on the project's complexity, material requirements, and production scale.