Hey there, I hope you are having a good day. Printed circuit boards (PCBs) are a popular topic in the electronic world and we also know that PCBs have revolutionized circuits. They not only provide a solid base but the material used in the PCBs helps the circuit to function properly by protecting the circuit from factors like external radiation. These are present in different materials that divide the working, stability, and reliability of the circuit. In recent years, there has been a significant change in the types and strength of PCBs and this depends on the materials used in the manufacturing of these boards. We are interested in studying the advanced materials used in the manufacturing of PCBs and knowing the right type of material for the right circuit.

In this article, we’ll start from the basic introduction of the advanced material and will try to understand why it is better to replace the traditional material with the advanced one. After that, we’ll see some important categories of the advanced materials used in the production of PCBs that are important to meet the needs of the latest technologies.

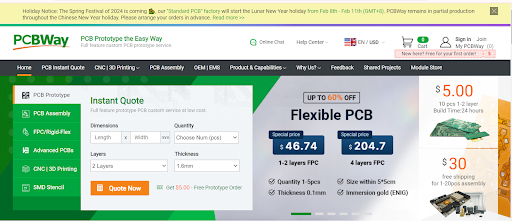

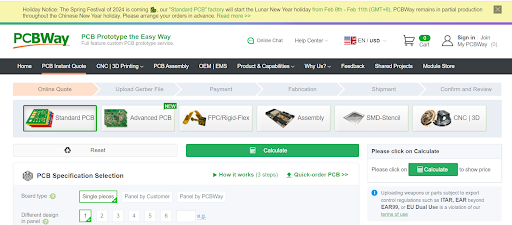

Where to order PCB?

Before going forward, let me first tell you where you manufacture your PCBs with these materials. PCBWay Manufacturing House provides almost all of these materials for PCB manufacturing. PCWay provides the best services when it comes to PCB designing. I personally use PCBWay for all my PCB orders and always get the best results.

Advanced Material of PCBs

The transformation of PCBs in recent years is because of the high quality and advanced materials used in manufacturing and this not only has improved the life span of the PCBs but also has a major impact on the circuit performance. The advanced materials are referred to as:

"The advanced materials for PCB manufacturing are the new material or the improved existing materials used in the manufacturing and design of the latest PCBs that help to meet the requirements of the advanced PCBs."

With the advancement in technologies, there is a requirement for faster, smaller, and more efficient electronics, and that in return, has enhanced the need for advanced PCBs. These requirements are fulfilled by using the advanced and more efficient material that helps to meet the need of the time. These materials are responsible for innovating the PCBs and these are not only the trend but are the essentials that are required to meet the requirements of contemporary electronic applications.

The advanced materials are better in performance and provide high-speed data transmission from one end to the other which is the main focus of the advanced digital electronic equipment.

PCB Advanced Material Examples

Here is a list of almost all the important advanced materials that are extensively used in the PCBs nowadays and play a crucial role in the improvements of the PCB industry:

Advanced PCB High-Speed Laminates

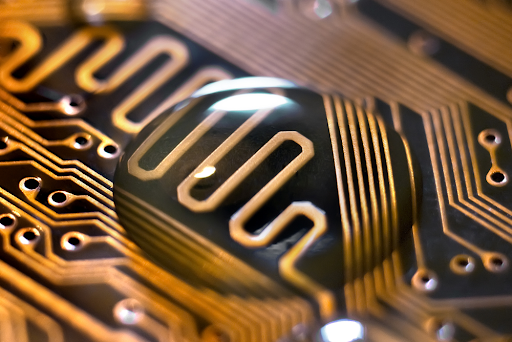

The traditional material is not able to overcome the advanced problems and boundaries of the bandwidth. The high-frequency circuits are introduced in the market that perform complex duties and these circuits are successful only when high-frequency PCBs are used. For this purpose, high-speed laminates are used for the manufacturing and design of the PCB. these cutting-edge laminates are the new generation of high-frequency materials for PCBs tailored for high-frequency applications.

High-Speed Laminates Properties in PCB

These laminates have an exceptionally low dielectric constant (Dk) that ensures minimal signal distortion. This property makes the PCB capable of dealing with the speed of light making the circuit work faster and better to match the new trends and requirements of the technology.

The minimal signal loss helps this material to provide another feature to PCB which is the negligible dissipation factor (Df). It maintains the signal integrity and provides low heat dissipation. One must be kept in mind that it results in efficiently dealing with the heat problems of the circuit.

The thermal stability of the high-frequency laminates is a plus point that helps to achieve the advanced level outputs from the circuit. These laminates have the physical properties to bear the high temperature without causing any change in their shape.

Examples of High-Speed Laminates

The following are suitable examples that are widely used in PCBs:

Rogers RO4000 series

Taconic CERFREE

PTFE (Polytetrafluoroethylene)

FR-4

Isola Isola-Tate FR-408

LCP (Liquid Crystal Polymer)

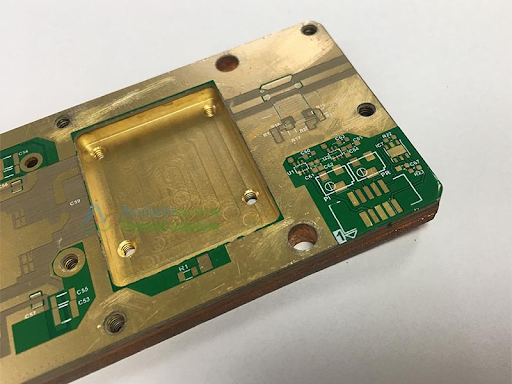

Metal Core PCBs as Advanced PCB Material

The metal core PCBs (also known as the MCPCBs) are the specialized PCBs that has the metal base as the substrate. The most common metal-based PCB types are listed below:

Aluminum

Copper

Steel alloy

Out of these aluminium-based PCBs are the most cost-effective. One evidence of this statement is, that it has high heat resistance therefore, such PCBs have a long life. Hence, the low heat dissipation results in the better performance of the circuit for a long time.

On the other hand, if the user wants high performance then the copper-based MCPCBs are a better option than the previous one. Copper is considered one of the most reliable conductors because of the physical arrangement of its atoms therefore, using it in the PCB is the best way to get the highest performance. This is the most commonly used material for the PCBs but it is more expensive the the aluminum PCBs.

Another important metal in regard is steel which is harder than the other two options mentioned before. Because of the tightly packed structure, this type of PCB has less conductivity but the plus point is, that these have excellent heat dissipation.

As a result, the specific type of the metal core PCB is used for the specific type of the circuit by keeping the thermal and other characteristics of the PCBs. These types of materials are used in PCBs because they have features like heat dissipation, less distortion, good dimensional stability, etc.

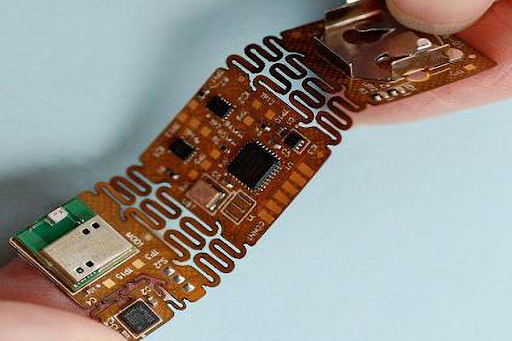

Advanced Flexible Material for PCBs

The flexible PCBs are one of the most trending type of PCBs that have the ability to make space in any type of the circuit and does not cause any major performance change. The advanced technology has made the circuit small and more flexible, therefore, there is a need for the PCB that is flexible and can bear the load of the high calculation and processing. These are made with lightweight, thin, and flexible materials and lead to a high range of applications in all types of circuits.

These PCBs are made on different scales of size and thickness and can be bent like a rubber therefore, are considered the ideal PCBs for wearables and other such technologies. The most commonly used flexible materials for PCBs are

LCP (Liquid Crystal Polymer)

PEN (Polyethylene naphthalate)

PET (Polyethylene Terephthalate)

PI (Polyimide)

PTFE (Polytetrafluoroethylene)

Flexural FR-4

Coverlay films (PI, PET, etc.)

Metal foil (copper, aluminium)

Adhesives (acrylic, epoxy)

Hence in this way, we have seen different type of advanced materials that are used in the PCBs and are making them more efficient and up to date. We started with the basic introduction of the advanced materials in the PCBs and then we understood different types of the advanced material that is revolutionising the PCB industry. The high-speed laminates, metal core PCB, and the flexible materials in the PCBs are important materials in this regard. If you know other such materials that are most common and suitable for advanced PCBs then share with us through the comment section.