Hello learners! I hope you are doing good. Today, we are learning about an important member of the gas sensor family, which is the MQ-2. When it comes to detecting or measuring smoke or gas, the MQ series gas sensors are widely used components in circuits. These sensors come with an operational amplitude comparator and a digital output pin therefore, they have applications in multiple fields of life. Mostly, it is used in Arduino projects where it senses the gas and the information is fed into the Arduino to allow the circuit to work according to its digital output.

In this article, we are going to discuss the basic introduction of this sensor in detail, along with the datasheet. Moreover, we’ll know its pinouts in detail and will see some important circuit diagrams. Moreover, we’ll try to figure out the workings and applications of this sensor in different domains to understand the core concept. This is going to be a detailed article on the MQ-2 sensor, so let’s get started.

MQ-2 Smoke/Gas Sensor Introduction

The MQ-2 is a metal oxide semiconductor (MOS) gas sensor and one of the most widely used sensors in the MQ series. We know that MOS sensors are known as Chemiresistors because there is a sensing material in them that works based on the change in its resistance when it is exposed to the reactive gas. Hence, when using the MQ-2 in the circuit, it can detect multiple gases and provide the digital values of change in the gases at its output pin. The list of gases this sensor can detect is given next:

- Liquified petroleum gas (LPG)

- Smoke

- Alcohol

- Propane

- Hydrogen

- Methane

- Carbon Monoxide

This sensor is particularly suitable to detect combustible gases, smoke, and other pollutants. Basically, it consists of the tin dioxide (SnO2) semiconductor gas sensor, a comparator (using the op-amp), and necessary supporting components.

MQ-2 Smoke/Gas Sensor Datasheet

Before using any electrical component, it is important to study its datasheet. The datasheet has multiple characteristics, and some of these are mentioned below:

MQ-2 Smoke/Gas Sensor Basic Parameters

Here is a table that provides the basic details of the MQ-2 smoke/gas sensor:

Parameter |

Value |

Units |

Model Number |

MQ-2 |

N/A |

Sensor Type |

Semiconductor |

N/A |

Standard Encapsulation |

Bakelite (Black) |

N/A |

Detection Gas |

Combustible Gas & Smoke |

N/A |

Concentration Range |

300-10000 ppm (Combustible Gas) |

ppm |

Loop Voltage (Vc) |

≤ 24 V DC |

N/A |

Heater Voltage (VH) |

5.0 V ± 0.2 V |

DC/AC |

Circuit Load Resistance (RL) |

Adjustable |

Ω |

Heater Resistance (RH) |

31 Ω ± 3 Ω |

Ω (Room Temp.) |

Heater Consumption (PH) |

≤ 900 mW |

N/A |

Sensing Resistance (Rs) |

2 KΩ - 20 KΩ (in 2000 ppm C3H8) |

Ω |

Sensitivity (S) |

Rs(in air)/Rs(1000 ppm isobutane) ≥ 5 |

N/A |

Character Slope (α) |

≤ 0.6 (R5000 ppm/R3000 ppm CH4) |

N/A |

Temperature & Humidity |

20°C ± 2°C; 65% ± 5% RH |

N/A |

Standard Test Circuit (Vc) |

5.0 V ± 0.1 V |

DC |

Standard Test Circuit (VH) |

5.0 V ± 0.1 V |

DC/AC |

Preheat Time |

Over 48 hours |

N/A |

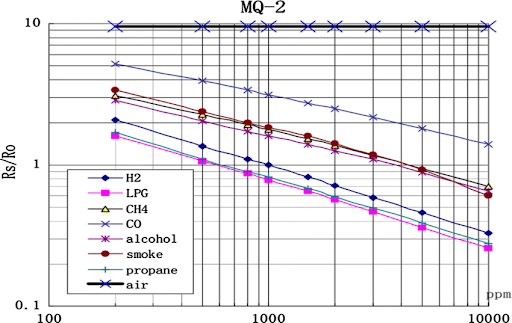

MQ-2 Smoke/Gas Sensor Sensitivity Graph

The sensors can detect multiple gases, and the sensitivity of the resistive material is different for all of them. Based on the multiple experiments and the specification, here is the sensitivity graph for the MQ-2 smoke/gas sensor:

MQ-2 Smoke/Gas Sensor Sensitivity Graph

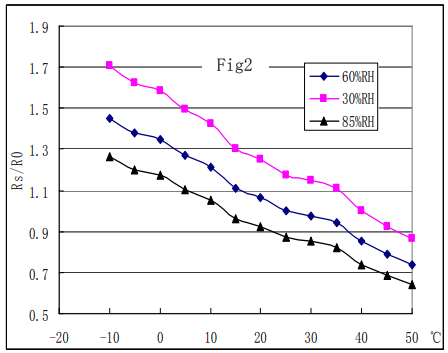

The sensitivity material is affected not only by the type of gas but also by other parameters such as humidity and temperature. Here is the graph that shows the details:

If you want to know more details about the datasheet, then here is the link to it:

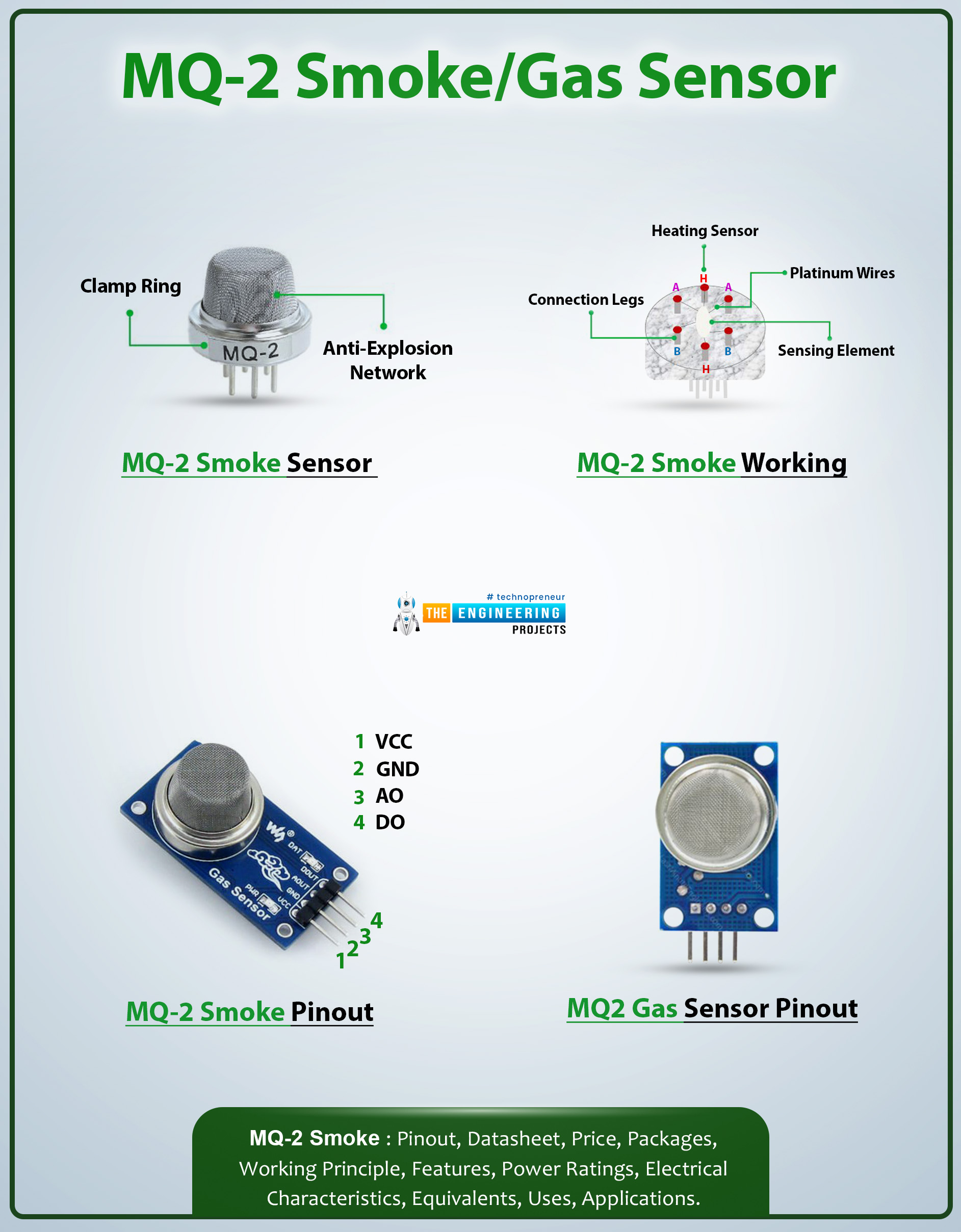

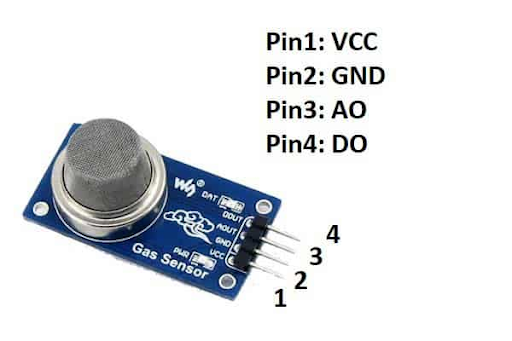

MQ-2 Smoke/Gas Sensor Pinout Configuration

The MQ-2 smoke/gas sensor has four pins, as shown below in the image:

The pin arrangement may vary depending on the model. Here, one must know that the DOUT pin is not always present, but some models do not have it, and in such cases, the analogue pin AO is the output pin. The details of each pin are given next:

Pin Number |

Pin Name |

Function |

1 |

VCC |

Supplies power to the sensor (typically 5 volts DC) |

2 |

GND |

Ground connection |

3 |

DOUT (optional) |

Digital output pin (usually pulled high when no gas detected, goes low when gas detected) |

4 |

AOUT |

Analog output pin (voltage level varies depending on gas concentration) |

The internal structure is shown below to add more detail in this discussion:

MQ-2 Smoke/Gas Sensor Packages

Package Type |

Description |

Pros |

Cons |

Applications |

Breakout Board |

Sensor mounted on a board with labelled pins and components. |

- Easy to use. - Provides stable operation. |

- May not have advanced features. |

Hobbyist projects, educational use, gas detection. |

Integrated Module |

Sensor with additional circuitry like a microcontroller. |

- Advanced features (calibration, digital output). |

- Higher cost. - May be less customizable. |

Industrial applications, gas detection systems. |

MQ-2 Smoke/Gas Sensor Alternatives

Sensor Type |

Examples |

Electrochemical Sensors |

Figaro TGS series, Sensirion SGP series, Amphenol NovaSens SC series |

Improved MOS Sensors |

Sensirion SPS30, Shinyei Figaro TGS822, and Amphenol NovaSens SCS series |

Optical Sensors |

Laser-based gas detectors, Infrared (IR) gas sensors, and photoionization detectors (PIDs) |

Other Alternatives |

MEMS-based gas sensors |

Biomimetic sensors |

In addition to all these, the MQ series has multiple members that are widely used in place of MQ-2. These may include

Where to Buy MQ-2 Smoke/Gas Sensor

Along with millions of other products, sensors like MQ-2 smoke/gas sensors are available at the following platforms:

eBay

Amazon

AliExpress

MQ-2 Smoke/Gas Sensor Working Principle

The working principle and characteristics of the MQ-2 are easily understood by studying the internal structure in detail. Here is the detail of each part, and we’ll discuss the working principal using the following structure:

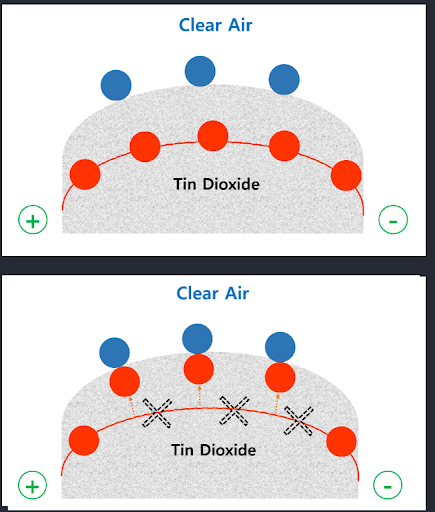

As mentioned before, the MQ-2 smoke/gas detector works on the principle of chemisorption. It is defined as:

"Chemisorption is the process by which the molecules of the material adhere to the solid surface because of the chemical bonding."

In the case of MQ-2, chemisorption is the process in which the gas molecules surrounding the sensor interact with its surface material and cause a change in the electrical resistance.

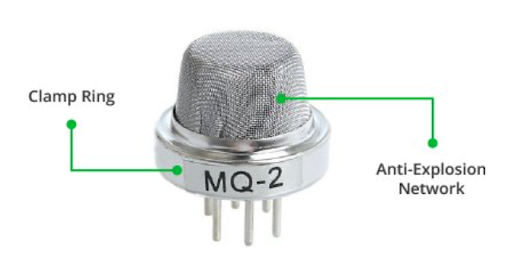

It is a heat-driven sensor, therefore it is covered with two layers of steel mesh. These layers are referred to as the anti-explosion network. This sensor is designed to detect combustible gases; therefore, the anti-explosion network is responsible for the protection of the heater element from the surrounding gases.

This network is in the form of a mesh so that it filters the suspended articles and allows only gases to reach the internal sensitive circuit. A copper plating is used to secure the mesh at its place.

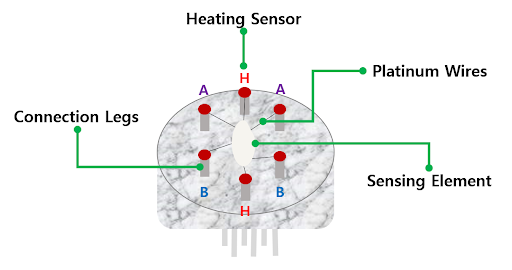

When the mesh is removed, the following structure is seen:

This star-shaped structure is responsible for the detection of the gas. Here is the explanation of each element:

- The sensing element lies in between all the other elements. It has a coating of tin oxide (SnO2), which is heated to 200-300 °C. This temperature activates the sensing element so that it may absorb the oxygen from the surrounding air. As a result, a depletion region is formed that increases the overall sensor resistance.

- The H indicated the sensing element heaters. Usually, it is a Nickel-Chrominum coil (conductive alloy).

- The A and B are the signal-carrying leads that are connected with the platinum wires. Through these wires, the A and B connect with the sensor element body. These are responsible for the small changes in the current values.

Once the gas enters this internal chamber, it reacts with the depletion region of the sensing element. As a result, the amount of oxygen decreases depending on the amount of the external gas, and as a result, there is a change in the resistance. The magnitude of this change determines the amount of combustible gas surrounding the gas sensor.

The sensor has a voltage divider circuit that converts the change in resistance into the output voltage, which is then sent as an output through the pin.

MQ-2 Smoke/Gas Sensor Features

Most features of this sensor have been discussed so far in this article, but here is a quick revision of these features:

- It detects the combustion gases around it, and the structure is protected through an anti-explosion network. The other gases surrounding the sensor do not have any effect on its working in normal conditions.

- In most of the models, there is only the analogue pin, whose value is potentially related to the detectable gas concentrations.

- Some modules have a digital output as well, which is indicated by DOUT.

- The calculation of the resistance in this case is followed by the formula given next:

This is a simple-to-use sensor that is compatible with multiple circuits. Another feature that supports its importance is its low cost and high-quality performance.

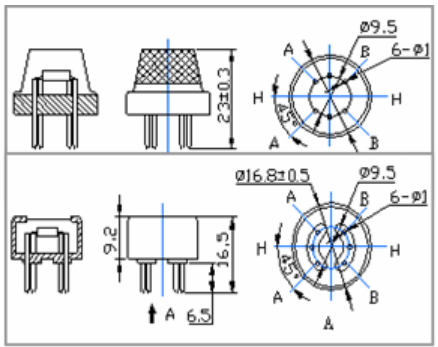

MQ-2 Smoke/Gas Sensor Physical Dimensions

The following table shows the dimensions of this sensor:

Dimension |

Value |

Units |

Diameter |

20 |

mm |

Height |

30 |

mm |

Pin Length |

4-5 |

mm |

Weight |

~8 |

grams |

MQ-2 Smoke/Gas Sensor Applications

The smoke and gas detector sensors are used in different ways in the project and are one of the most important parts of such circuits. Here are some basic examples of MQ-2 smoke/gas sensor applications:

Residential gas leak detection (homes)

Industrial gas leak detection (factories)

Basic fire alarm systems (buildings)

General air quality monitoring (sensor network)

Portable gas detectors (personal safety)

Educational electronics projects

Hence, today we have learned the basic information and its detailed specifications. We started with the basic introduction of the MQ-2 sensor and how it works. We understood its features, and workings and read the datasheets. In the end, we see some simple applications in different domains of life. I hope this was an informative guide for you, and if you want to add more information in it, you can comment to us.