Emerging Trends in PCB Technology

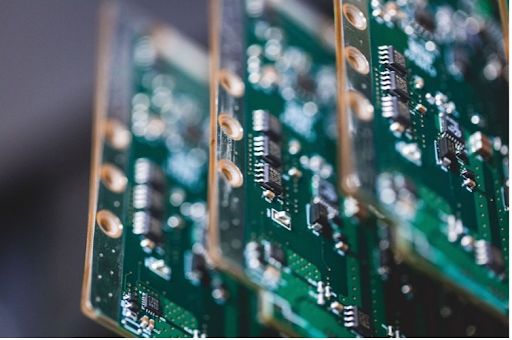

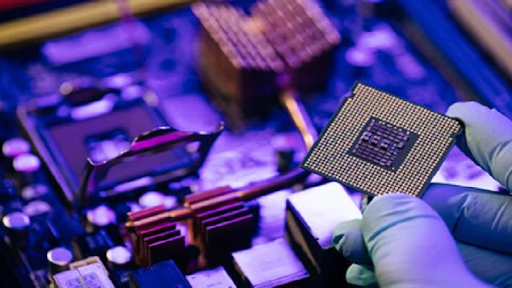

Printed circuit boards are the most important and basic component of the electronic industry. These boards have made it possible to create and run circuits on every level and have served as the backbone of any electronic device. With the growing demand for technology, PCBs have gone through multiple evolutions. The transformation of PCBs has made it possible to create innovative and better electronic circuits.

Today, we are talking about the emerging trends in PCB that are reshaping electronic circuits and the components used in innovative designs. But before this, it is important to understand the importance of using the emerging trends for the circuits.

Importance of Using Trending Technologies in PCBs

PCBs are versatile components, and not all PCBs are ideal for a particular type of circuit. However, it is always advisable to use the most trending technologies to meet the needs of the time, especially in the case of designing Multilayer PCB. Here are some important and obvious advantages to using the trending technologies:

Enhanced Performance

The enhanced technologies are made to provide better functionality and performance. The researchers are working on providing the best techniques to make the lower PCBs work more efficiently, even on low power. Experiments are being performed on different materials to improve electricity flow and resistance to heat.

Similarly, multiple techniques are introduced to reduce the size of components and boards to provide better accommodation for components in the boards. As a result, more components can be settled on the same board, and better performance is expected.

Reliable Results

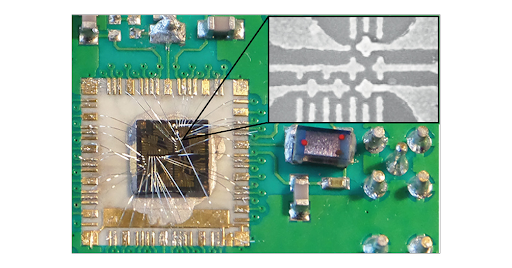

The advanced technology is more reliable because of the multiple experiments and research performed on PCBs. The advanced PCBs have a lower risk of failure and other related factors, and they have a longer life as compared to the older technology PCBs. For instance, in the latest PCBs, lead-free solder and other safe materials are used to ensure reliable working for a long time. Moreover, conformal coating is used as a coating to provide protection to the PCB against moisture, dust, and other contaminants that can harm the PCBs.

Versatility in PCBs

The advanced technology provides more versatility and variety in operations related to PCB functionalities. For instance, 3D printing technologies allow the user to create complex and smaller PCB designs that were almost impossible with the old and traditional techniques. For instance, laser direct imaging technology helps to improve the accuracy of PCBs; therefore, multiple operations can be performed on such PCBs with a lower risk of damage.

Emerging Trends in PCB Technology

Technology is all about following the trends that people want. In the electronic industry, trends do not change rapidly, but there is still a need to follow the emerging and latest technologies to match the requirements of devices and for better component selection. Here are some trends that are present in the market for PCB and have scope in the future as well.

Flex and Rigid-flex PCBs

The material of the PCB is the most obvious and important factor to consider when choosing the type of board. Flexible PCBs are trending in the market because of their ability to adjust to different shapes and inconvenient places. The market for electronic devices requires a type of PCB that can fit into wearables and other small places and can accommodate the shape of the latest devices. People are moving towards flexible and rigid-flex PCBs because they are convenient, reliable, and durable, even in challenging situations.

It has been seen that flex and flex-rigid PCBs have more life than simple hard and inflexible boards. Moreover, these PCBs can accommodate a larger number of components because the electrical traces are flexible and can conduct electricity at a longer distance. It is evident that the electricity in these PCBs faces low resistance therefore, the conductivity is enhanced.

Miniaturization and HDI PCBs

This is the era where everything can be made better using different technologies. Wearable devices are trending, and this has led to the success of miniaturization and HDI PCBs. Miniaturization not only makes the PCB smaller, but these are more powerful versions of the bigger PCBs because of the advanced technologies and best material used for electrical conductivity.

In small PCBs, high-definition interconnections are used for the best electrical conductivity and traces. These microvalves and multiple-layer PCBs provide better performance and are one of the most trending PCBs in the industry.

3D Printing

3D printing is the emerging trend in prototyping, and it provides convenience during the design process. It is used to create the conductive traces within the multi-layer intricate PCBs. This has made rapid customization and provided variety for prototyping and ideal design formation in PCBs. People are moving towards this technology because it allows them to use their creativity and make possible results. PCBWay is one of the best PCB Fabrication houses and provides the best 3D printing.

Quantum Dots and Nanotechnology

Quantum dots and nanotechnology are the trending technologies for the devices for medical industry and display applications. These are the tiny semiconductor particles used in the PCBs and provide different colours and lights when the electricity is passed through them. Such types of PCBs are trending in the advertising, market, and medical industries, where attractive and unique colours are required to distinguish different elements.

Smart PCBs for IoT

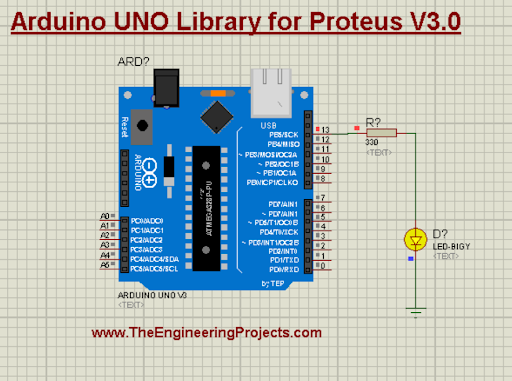

The integration of IoT technology into the PCBs is making them smarter. These PCBs are the heart f the connected world and require communication between different devices. IoT provides the functionality of different wireless communication and connections with the help of different controllers, sensors, modules, etc that enable the devices to collect and transmit the data. These smart PCBs provide automation and create the smart networks that are trending in every field.

Best PCB Company Working on the Latest Techniques

The first step in innovative electronics is the application of the latest techniques to the PCBs. It seems PCBWay Fabrication House knows it very well because it has been working on emerging technologies to provide the latest functionalities in its PCBs. It is a Chinese company that started in 2003 and since then, it has gained a great number of customers and provides its services almost all over the world through its website. It seems like the motto of this company is to win the hearts of customers all over the world through their high-quality and affordable products and services.

This company has manufacturing facilities in multiple countries, including Shenzhen and China and the sales and support network of PCBWay makes it one of the most reliable companies around the world.

Innovative Techniques of PCBWay

PCBWay is committed to providing the exact product according to the customer’s expectations. It offers multiple types of plates, including Rogers, copper substrates, aluminium substrates, high-frequency high-speed HDI for miniaturization and other latest techniques. The following is a list of the basic techniques PCBWay uses to provide trending products and services:

impedance control

HDI blind buried hole

Thick copper PCB

Multi-layer special stack-up structure

Electroplated nickel gold/gold finger

Electroless Nickel Electroless Palladium Immersion Gold (ENEPIG)

Shaped holes

Deep Groove

You can get details on each of them here . The research department of this company works day and night to provide innovative and demanding products when the customer contacts them for an order or suggestions.

Bottom Line

Printed circuit boards have to be more versatile and up-to-date all the time to meet the needs of the technical world. These are the backbones of the electronic industry, and the competition among different companies makes it compulsory to use trending technologies in PCBs. We have seen why it is important to use the latest technology in the PCB and what some basic and trending technologies are. In the end, we have discussed one of the most popular companies, PCBWay, for the prototyping, manufacturing, and related tasks on the PCBs, and we have discussed some of the basic techniques it follows. I hope it was information for you.

1 user

1 user

Continue Wishlist

Continue Wishlist

Getting Started Guide

Getting Started Guide

Help Center

Help Center

Contact us

Contact us

Doist Blog

Doist Blog

Privacy

Privacy

Security

Security

Terms of Service

Terms of Service

What's new: Channel Descriptions

What's new: Channel Descriptions

Printed Circuit Boards

Printed Circuit Boards syedzainnasir

syedzainnasir 0 Comments

0 Comments

Emerging Trends in PCB Technology

Emerging Trends in PCB Technology

Monday, November 6, 2023

Monday, November 6, 2023