How To Build the PCB Best - JLCPCB

- The SMT production plant was relocated to an advanced factory, expanding from the previous 32 machines to 72 placement machines.

- expanded from the original 4 SMT production lines to 9 SMT production lines to support more production.

- Parts have increased from 30,000 kinds to more than 80,000 kinds.

- Added black, blue, red PCB assembly service.

×

![]()

1 user

1 user

Continue Wishlist

Continue Wishlist

Getting Started Guide

Getting Started Guide

Help Center

Help Center

Contact us

Contact us

Doist Blog

Doist Blog

Privacy

Privacy

Security

Security

Terms of Service

Terms of Service

What's new: Channel Descriptions

What's new: Channel Descriptions

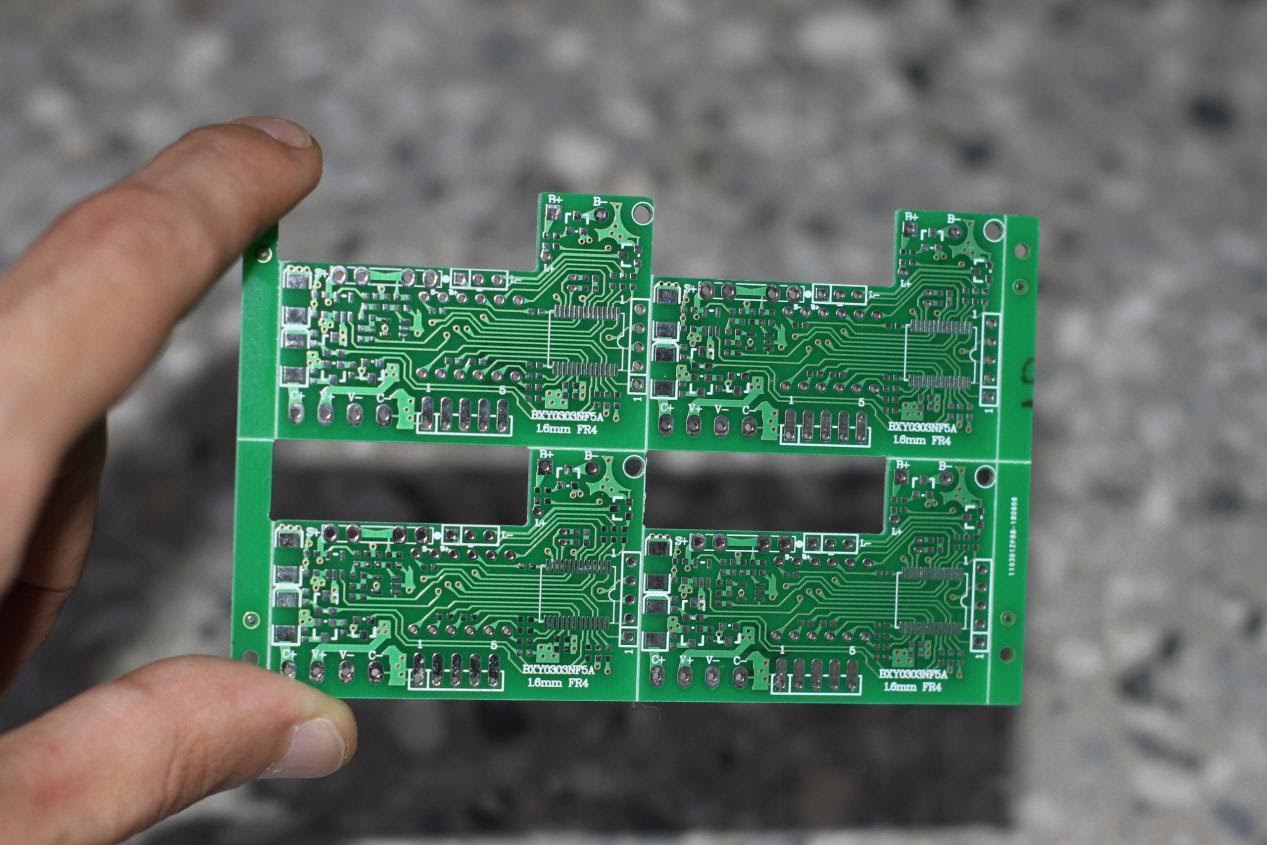

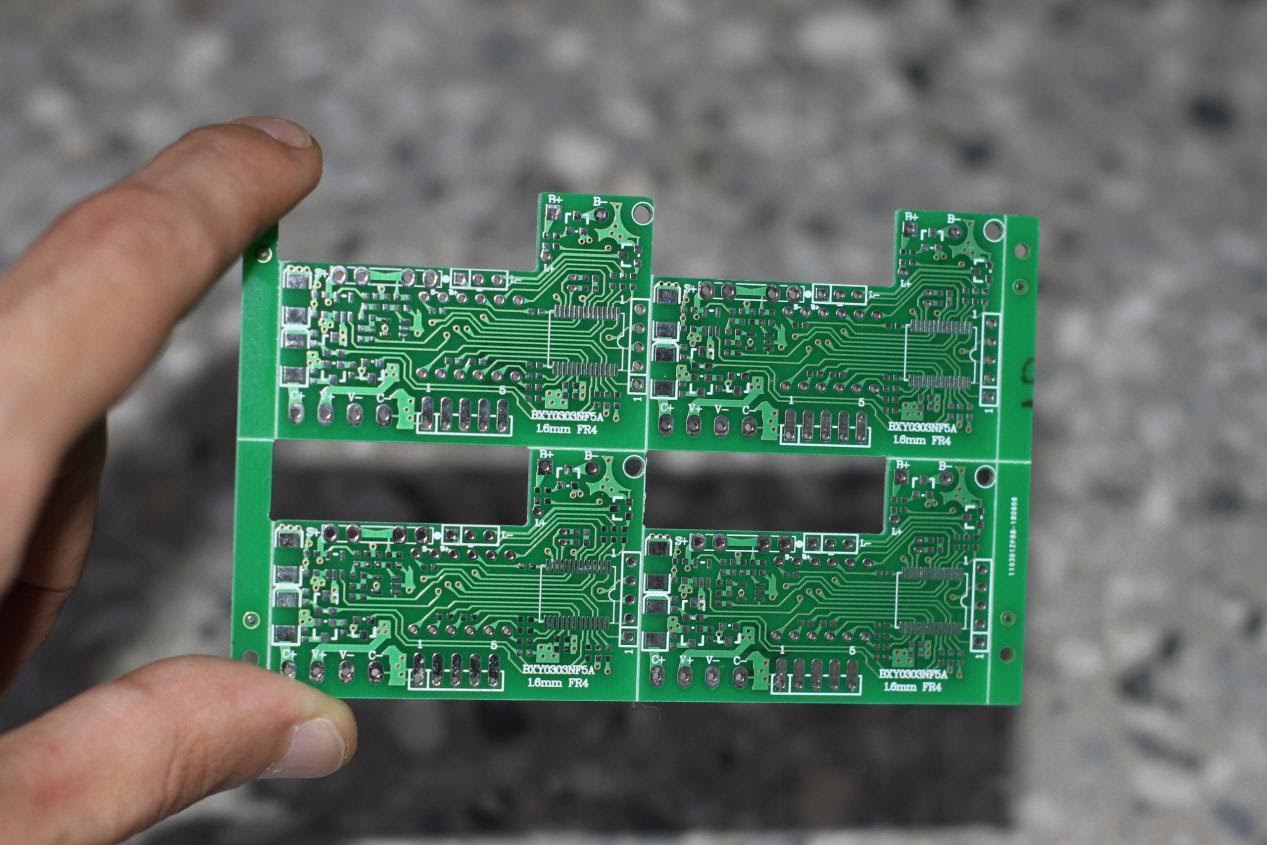

Printed Circuit Boards

Printed Circuit Boards ayeshayounas

ayeshayounas 0 Comments

0 Comments

printed circuit board

pcb

printed circuit board formation

printed circuit board ideas

printed circuit board

pcb

printed circuit board formation

printed circuit board ideas

Wednesday, February 10, 2021

Wednesday, February 10, 2021