A Tour to JLCPCB - Fabrication House

A Quick Review about JLCPCB

JLCPCB turns out to be an ideal choice for meeting your needs and expectations when it comes to providing quality product. They don't brag about their skills and ability to fabricate an accurate PCB, but their excellence does. Customer satisfaction is their first priority rather than achieving financial goals Getting new customers is not a big deal unless you have an ability to retain your previous customers which JLCPCB truly understands and provides flawless customer service, allowing customers keep coming back for what they have to offer.

How PCBs are Fabricated?

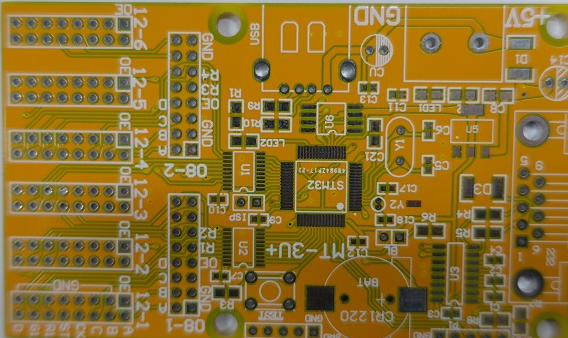

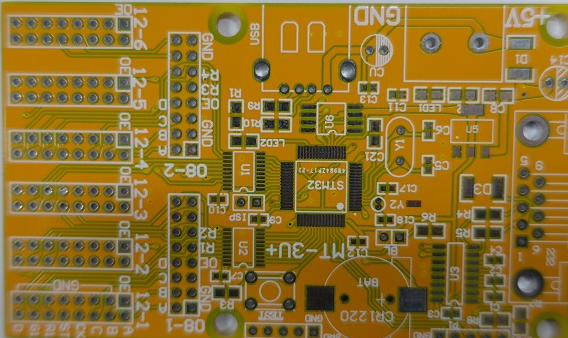

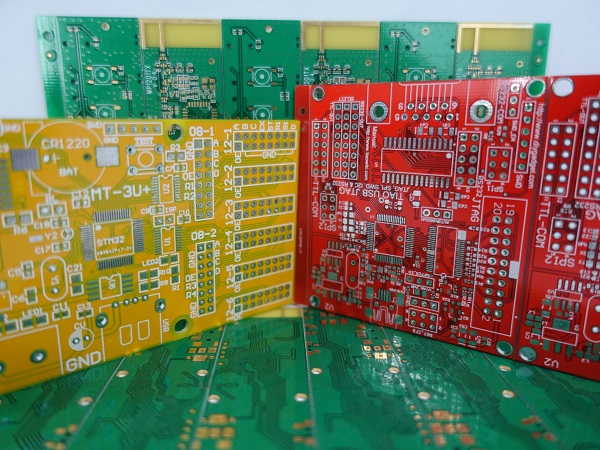

Some terms are essential to know for your better understanding JLCPCB uses for fabricating a simple board. A simple PCB is composed of different layers and each layer comes with its own specific function. These layers are joined together with the help of adhesive and heat which incorporate a single board capable of connecting different components electrically. The base material is composed of fiber glass and FR4 is the most common fiber glass used in recent times. However, phenolics and epoxies are also used but they are not as durable as FR4. There resides a copper layer on the substrate. Heat and adhesives are used to laminate copper layer on the substrate. Some boards come with copper layers on both side of the board, however, it depends which type of board you intend to fabricate. Single layer PCB have copper tracks on one side of the board while double layer PCB comes with tracks on both side of the board. Multilayer PCB comes with a combination of single sided and double sided PCB, where multiple layers are joined together to connect components on the board. Soldermask layer resides over a copper layer which is used to insulate copper tracks in order to avoid any conduction in case any direct contact happens with some metal. Silkscreen layer exists on the top of all layers which is used to print symbols or numbers on the board that give better understanding of the board.Through Hole and Surface Mount Technology

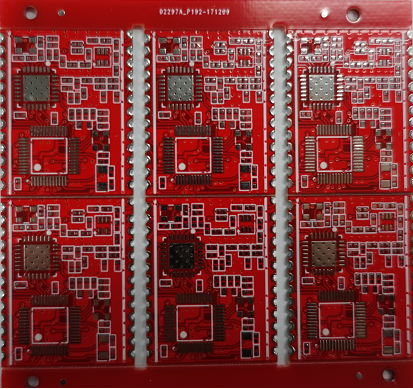

PCBs are fabricated using two technologies i.e Through Hole Technology and Surface Mount Technology. Using through hole technology they fabricate a PCB that comes with accurate hole, you can see from the diagram below, where vias are accurate and precise. Leads are used to pass through the holes which are then soldered on the other side of the board. In the Surface Mount Technology, PCB is fabricated in such a way where components are directly placed on the surface of the board. You can make use of any technology based on your needs and requirements.

Quality Assurance

What I like most about JLCPCB, they don't compromise on quality no matter how many PCB pieces you intend to fabricate. Advanced production lines are installed in their fabricating house that results in precise and an accurate board. PCBs are 100% AOI tested and fabricated using A level boards material.Advanced Tracking System

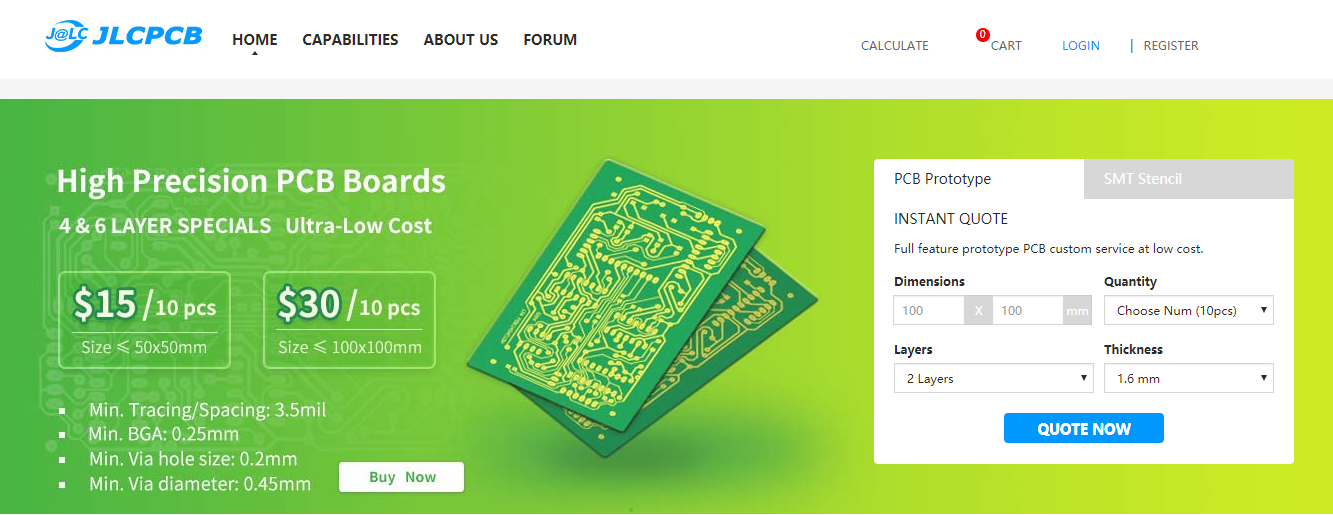

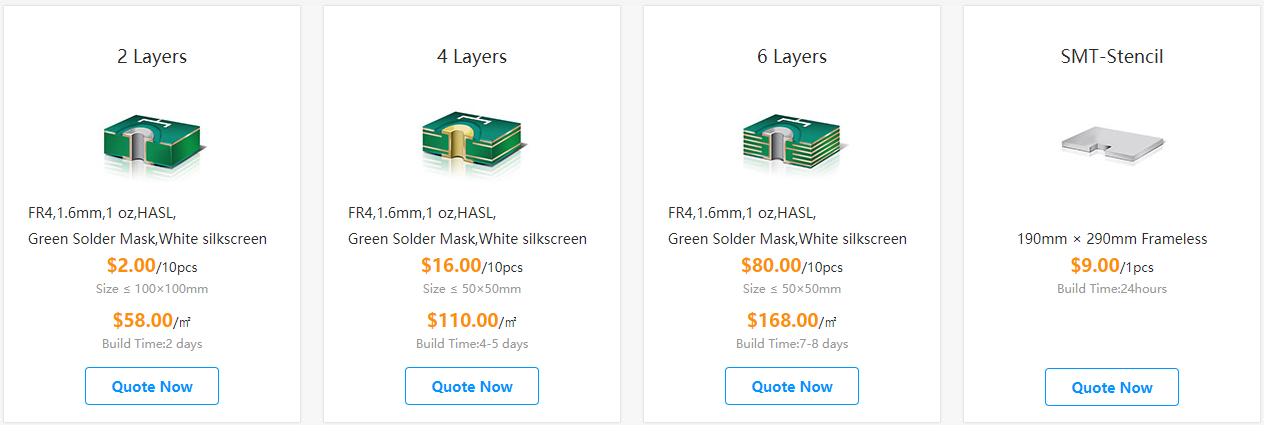

Getting a quote is very easy and hassle free, you just need to upload gerber file in order to get instant quote. You don't need to worry about the status of your order, as they come with advanced ERP system that allows you to keep the track record of order processing status, setting you free from the fabricating process and allows you to keep focus on more preferable tasks like designing or other processes that make the PCB suitable for installing in the electronic project.

Quick Follow Up

Managing 8000 online orders daily seems like a hectic task but they come with a skilled staff that handles these orders very beautifully and keeps customers engage with regular follow up in the whole process of fabricating PCB.Economical Price

JLCPCB keeps an eye on the fabricating cost and provides an effective solution to your needs in an affordable price. Based on my personal experience, I'd highly recommend JLCPCB house for fabricating your PCB. They will provide best experience as they believe in maintaining a long lasting relationship with the customers by providing flawless service. That's all about review. I hope you have got a clear idea about this company and why you should prefer them over others. However, if still you feel skeptical or have any question, you can ask me in the comment section below, I'd love to guide you according to best of my expertise. Thanks for reading the article. Stay Tuned!×

![]()

1 user

1 user

Continue Wishlist

Continue Wishlist

Getting Started Guide

Getting Started Guide

Help Center

Help Center

Contact us

Contact us

Doist Blog

Doist Blog

Privacy

Privacy

Security

Security

Terms of Service

Terms of Service

What's new: Channel Descriptions

What's new: Channel Descriptions

Embedded Systems

Embedded Systems adnanaqeel

adnanaqeel 0 Comments

0 Comments

A tour to JLCPCB

Introduction to JLCPCB

Fabrication House JLCPCB

Advantages of JLCPCB

A tour to JLCPCB

Introduction to JLCPCB

Fabrication House JLCPCB

Advantages of JLCPCB

Thursday, April 12, 2018

Thursday, April 12, 2018