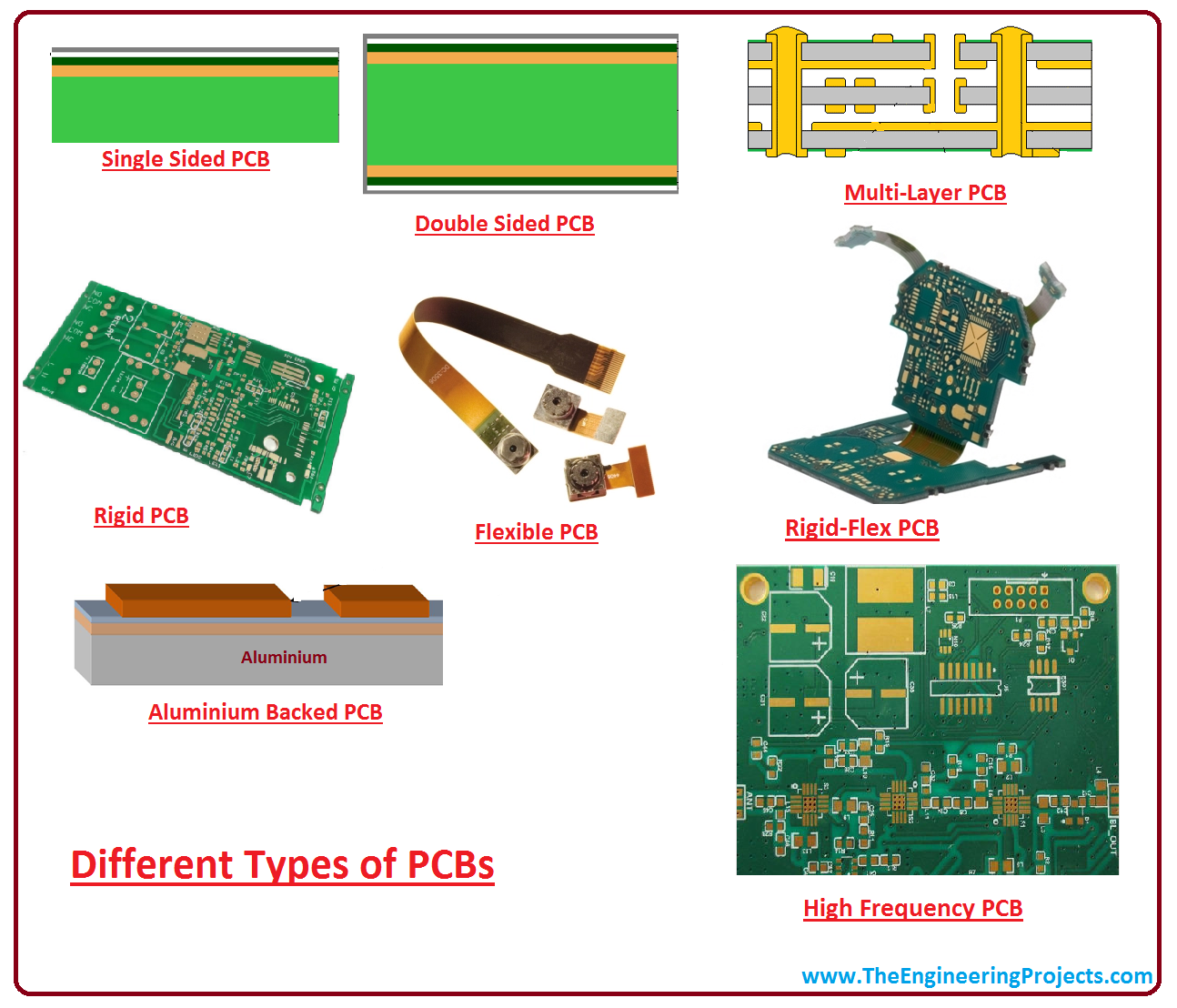

Different Types of PCB(Printed Circuit Board)

Hello Everyone! I hope you all are doing well. Today, I am going to share the 12th chapter in the PCB learning series. In today's lecture, we will have a look at the Different Types of PCB(Printed Circuit Board).

We are familiar with the PCB, it is a printed circuit board that contains traces, lines and paths to electrically connect electronic components. It consists of a substrate on which copper conducting material is laminated for creating an electrical connection between components.

Let's dive in and explore these types of PCB boards:

Types of PCB(Printed Circuit Boards)

Following is the list of available types of PCB types. You can choose any PCB based on your requirements:- Single-Layer PCB

- Double Layer PCB

- Multilayer PCB

- Rigid PCB

- Flex PCB

- Rigid-Flex PCB

- High-Frequency PCB

- Aluminium Backed PCB

1. Single Layer PCB

- A single Layer PCB contains only one layer of conductive copper foil.

- One side of the base material(substrate) is laminated with metal(normally copper) that is used to build an electrical connection between the components soldered on the board.

- Copper is mostly used for creating a conducting path because it acts as a good conductor and comes with low resistance.

- A solder mask is used on top of the copper layer which provides solid protection.

- On the top of the solder mask, there exists a silkscreen coating that is used for marking the elements on the board.

- Single-layer PCB is an ideal choice for beginners, as mostly used in simple electronics which don't involve complex circuitry.

- They are easy to manufacture and less time-consuming.

- Cheap cost and easy availability make these PCBs an ideal choice for hobbyists.

- These low-cost boards are widely used in many applications including stereo components, calculators, cameras, power supplies and printers.

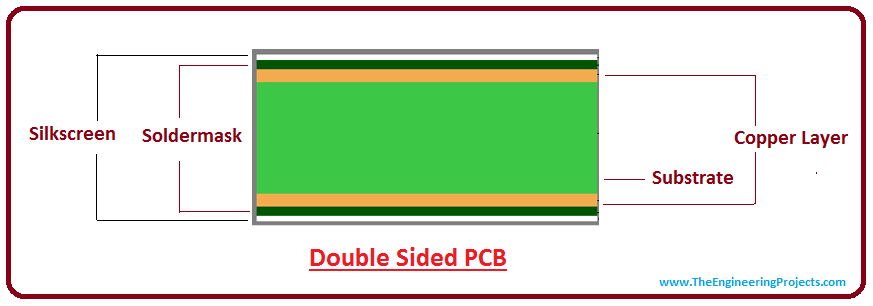

2. Double-Layer PCB

- Double-Layer PCB contains two layers of copper material and substrate material is present in between these copper layers.

- Both layers are connected to each other using holes(called vias) drilled into the boards.

- Components on these PCB boards are connected using two technologies i.e. Through Hole Technology and Surface Mount Technology.

- Double-sided PCB features a moderate level of complexity and is mostly used in applications including automotive dashboards, LED lighting, vending machines, amplifiers, HVAC system, instrumentation etc.

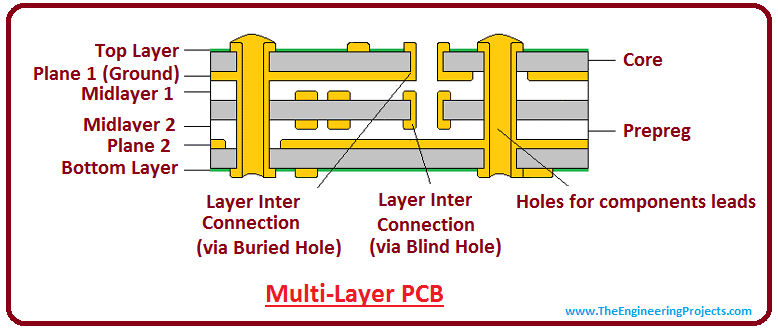

3. Multilayer PCB

- Multilayer PCB contains multiple layers of copper and is designed with a combination of single-sided and double-sided PCB boards.

- A layer of insulation(substrate material) is placed between each board in order to provide protection that prevents the components from burning in case of excessive heat.

- Multiple layers allow the professionals to design complex designs which help in accomplishing complex electrical tasks.

- The extra layers incorporated in the multilayer design are very helpful and often used for preventing electromagnetic interference emitted by the design itself.

- Multilayer PCBs are widely used in a number of applications including Satellite systems, GPS technology, Data storage, File servers and Weather analysis systems.

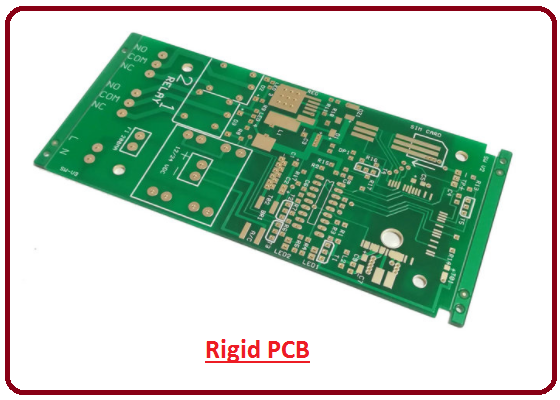

4. Rigid PCB

- Rigid PCB has a hard base material(substrate), normally of fiberglass/epoxy resin and provides strength to the circuits by making them rigid.

- A computer motherboard is an ideal example of a rigid PCB that is composed of rigid substrate material.

- The motherboard is a multilayer PCB that is designed to distribute electricity from the power supply and helps in creating a conducting path between different parts of the computer including CPU, RAM and GPU.

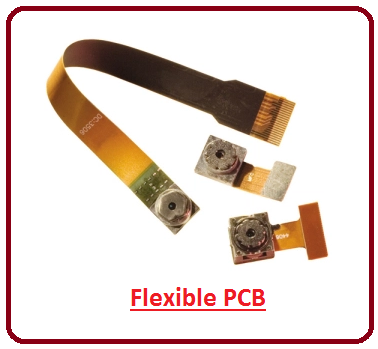

5. Flexible PCB

- Flexible PCB can flex or transform into any shape based on needs/requirements.

- Flexible PCBs are also referred to as Flex Circuit and use plastic material in contrast to rigid PCBs, which use fiberglass that provides rigidity and strength to the PCB.

- The conducting material used in these PCBs is mostly composed of polyester, polyamide or PEEK (Polyether ether ketone).

- These PCBs pertain to a high level of complexity and come with different layers ranging from single-sided, double-sided or multi-layer flex circuits.

- The flexible nature sets these PCBs apart from others as they can be folded and wrapped around the corner.

- In order to avoid environmental hazards, flexible PCBs are composed of materials that are resistant to high-temperature oils, corrosion-resistant, waterproof and shockproof.

- These flex circuits are used in a wide range of applications including Flex solar cells, LCD fabrication, Cellular telephones, automotive industries, Laptops, cameras, LEDs and many more.

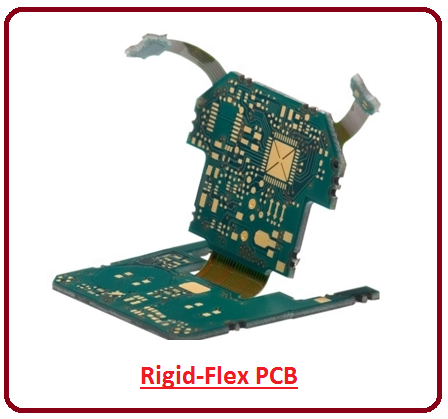

6. Rigid-Flex PCB

- Rigid-Flex PCB is manufactured when a flexible PCB is combined with a rigid PCB.

- This gives both flexibility and strength to the electronic product.

- Rigid-Flex PCB is more expensive and difficult to design as compared to Rigid or Flexible PCB.

- Less space required to construct a whole circuit and minimum weight makes these PCBs an ideal choice for handheld electronic devices including pacemakers, automobiles, cell phones and digital cameras.

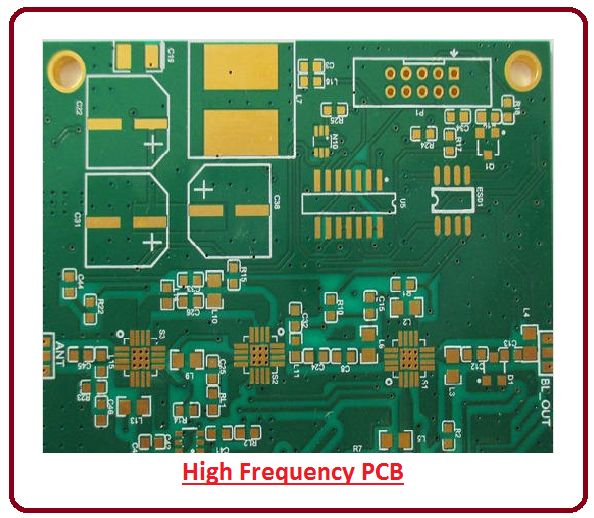

7. High-Frequency PCB

- High-Frequency PCB is slightly different in terms of construction and material used for traditional PCB and is capable of transmitting signals over 1GHz.

- These PCBs are often composed of materials like polyphenylene oxide, Teflon, and glass-reinforced epoxy laminate.

- Small dielectric constant makes Teflon, an expensive choice for high-frequency PCB and it also provides low water absorption and small dielectric loss.

- You must take some things into consideration before choosing high-frequency PCB for your projects like dielectric thickness, dielectric constant and power dissipation.

- The dielectric constant is the most important feature when it comes to choosing high-frequency PCBs because if the dielectric constant changes too quickly and is unable to maintain a constant state, it leads to corrupting the digital signal which affects the overall performance of the signal.

- Similarly, dielectric loss is directly proportional to the signal loss and it also affects the signal transmission quality. Smaller dielectric loss leads to smaller signal loss.

- High-Frequency PCBs, if used in a wet environment can affect the dielectric constant.

- The material selection for making these PCBs is very important, the material you pick must be resistant to heat and hazardous chemicals and provides strength and durability to the PCB surface.

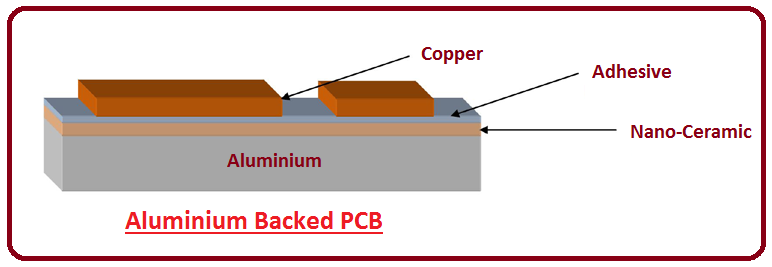

8. Aluminum-Backed PCBs

- Aluminum Backed PCBs are similar to copper PCBs with some exceptions i.e. Substrate in aluminum-backed PCBs is made up of aluminum.

- These PCBs are coupled with insulating material that provides less thermal resistance, avoiding the heat from transferring to its backing.

- Aluminum is inexpensive, making almost 8.23% of the planet's weight, and leads to the most economical manufacturing process.

- PCBs made up of aluminum are easily recyclable and non-toxic in nature.

- Aluminum is very durable than its counterparts like fiberglass or ceramic and pertains to less damage during the installation and manufacturing process.

- And aluminum is an ideal choice for dissipating heat from the circuit components, allowing the heat to transfer into the atmosphere rather than transferring it to the rest of the board.

- Aluminum Backed PCBs are widely used in high-output power applications including power supplies, automotive lights, traffic lights, motor controllers etc.

- Aluminum-baked PCBs also pertain to high mechanical stability and have the capability of bearing high mechanical stress.

- In contrast to fiberglass boards, aluminum-backed PCBs provide less thermal expansion, allowing the copper foil and insulation to stay placed on the board, hence helping in increasing the overall lifespan of the board.

That's all for today. In the next tutorial, we will have a look at the Single Layer PCB in detail. I hope you have enjoyed these different types of PCB. However, if still you feel any doubt or have any questions, you can ask me in the comment section below, I'd love to help you according to the best of my expertise. Stay tuned!

1 user

1 user

Continue Wishlist

Continue Wishlist

Getting Started Guide

Getting Started Guide

Help Center

Help Center

Contact us

Contact us

Doist Blog

Doist Blog

Privacy

Privacy

Security

Security

Terms of Service

Terms of Service

What's new: Channel Descriptions

What's new: Channel Descriptions

Printed Circuit Boards

Printed Circuit Boards adnanaqeel

adnanaqeel 1 Comments

1 Comments

different types of pcbs

types of pcbs

basics of pcbs

types of pcb

pcb types

different pcb

different types of pcbs

types of pcbs

basics of pcbs

types of pcb

pcb types

different pcb

Wednesday, March 14, 2018

Wednesday, March 14, 2018