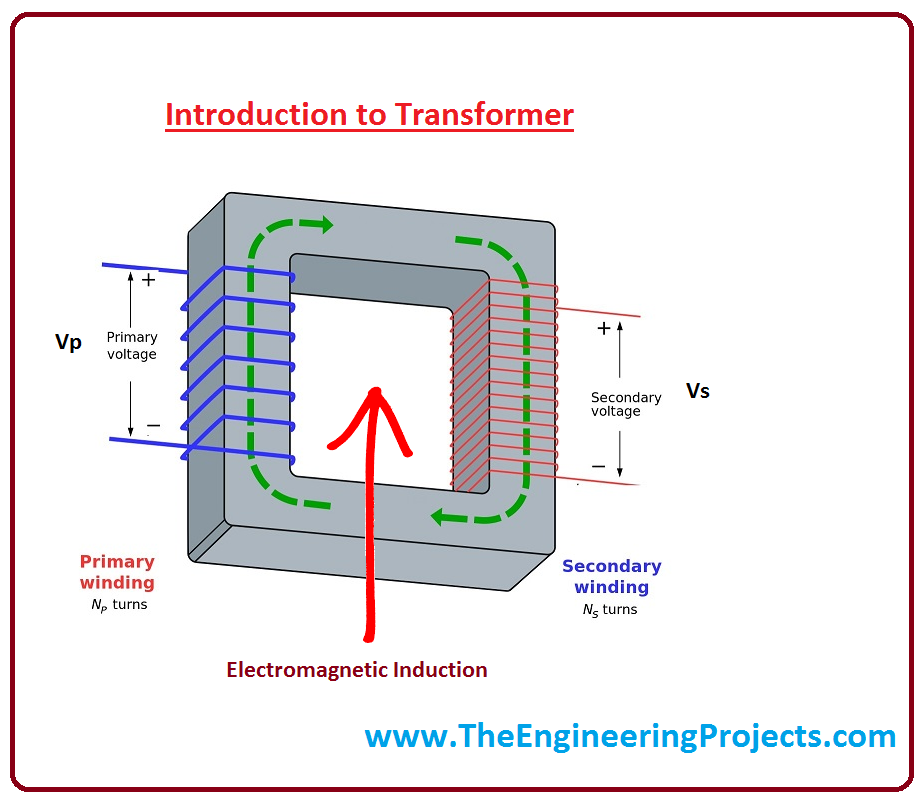

1. Introduction to Transformer

- Transformer is a simple static device that helps in transferring the electrical power between two circuits.

- Transformer works on the Faraday’s Law of Electromagnetic Induction.

- It is a process by which primary coil induces a voltage into the secondary coil with the help of magnetic induction. The coil windings are electrically isolated and magnetically connected around a common circuit called core.

- If we apply varying current in one coil, it results in creating a magnetic field and automatically induces the varying voltage in the secondary coil.

- Hence power is transmitted from one coil to another through the magnetic field.

- A slight change in current in transformers helps in increasing and decreasing the AC voltage in many electrical power applications.

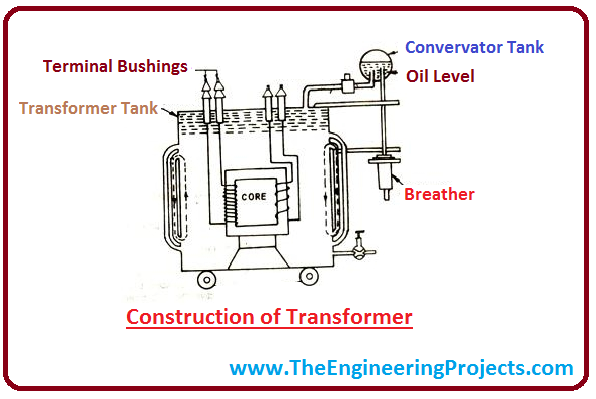

2. Construction of Transformer

- A simple static transformer is a linear device that consists of coils that are mutually inductive and steel core.

- The windings in the coil are insulated from each other and from the steel core.

- The whole assembly of windings and steel core are encased in a device called tank.

- The major purpose of the tank is to insulate the core assembly from the coil windings.

- In order to take out the terminals of transformer specific bushings made up of capacitor are used.

- Added amount of oil conservator is also used in the tank which provides cooling and reduces friction.

3. Mathematical Formulas for Transformer

Till now, we have seen the basic introduction and construction of Transformers, but when it comes to designing, then we have to make some mathematical derivations. In this section of this tutorial, I am gonna focus on some basic concepts of Transformers and will also share their mathematical formulas.Turn Ratio

- Transformer has a turn ratio which dictates the operation of transformer and the value of output voltage applied to the secondary windings.

- Turn ratio is defined as a number of turns of the primary coils divided by the number of turns of secondary coil.

TR = Np /Ns

If Ns > Np then it is called step up transformer

If Np > Ns then it is called step down transformer

Transformation Ratio

- Transformation Ratio is defined as the secondary voltage divided by the primary voltage. And it is denoted by K.

K = Vs / Vp or Ns/Np

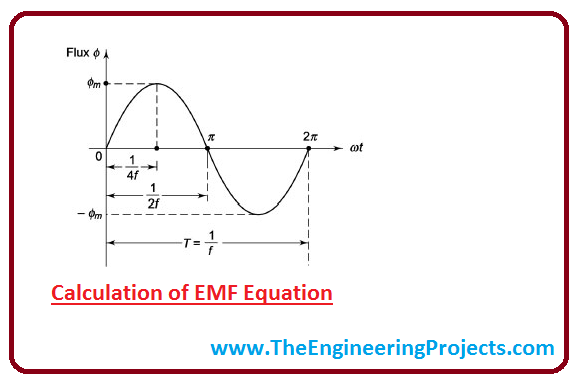

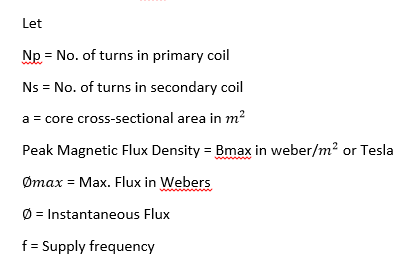

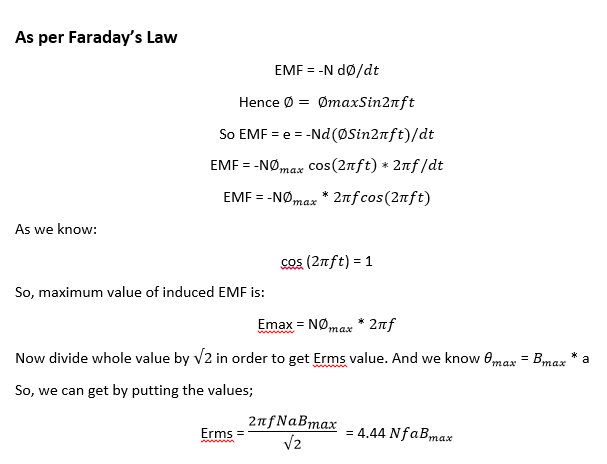

Transformer EMF Equation

- If we apply electrical source on the primary side of transformer, it will produce the magnetizing flux across the core of transformer.

- It must be a rate of change of flux that is connected to both, primary and secondary coils.

- According to Faraday’s Law of Electromagnetic Induction, changing flux in the coil must induce EMF in it.

- Suppose the flux created forms a sinusoidal function. As it is a rate of change of flux so it must be derivative of sine function which is a cosine function.

- We can easily get the rms value of the induced EMF if we get the rms value of cosine wave and multiply it with the number of turns of coils.

- Now let's have a look at the Faraday's Law of Electromagnetic Induction:

4. Types of Transformers

There are many types of transformers available in market but we can't cover them all in this tutorial. So, I am gonna just focus on those, which are used most commonly. Transformer can be differentiated into following types:Step Up Transformer

Transformer is known as step up transformer if the number of turns of coil in secondary coil is greater than the number of turns of coil in primary coil. In other words, when transformer is used to increase the voltage on the secondary coil it is called step up transformer.Step Down Transformer

Similarly, a transformer is known as step down transformer if the number of turns of coil in primary coil is greater than the number of turns of coil in the primary coil. Or if transformer is used to decrease the voltage on the secondary coil, it is called step down transformer.Impedance Transformer

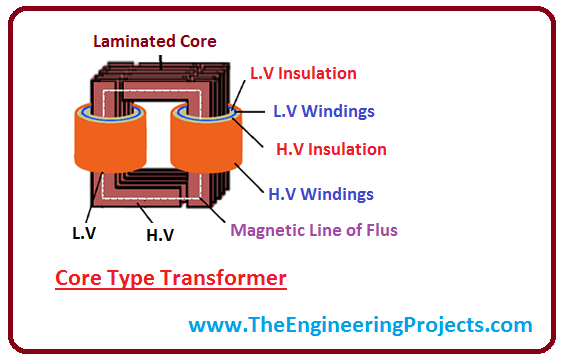

A transformer is called impedance transformer if it is used to deliver the same voltage to the secondary windings as applied to the primary windings. Hence output remains constant with respect to the input. This type of transformer is used for the isolation of electrical circuits or impedance matching.Core Type Transformer

Core type transformer comes with a cylindrical coils that are form-wound. In this transformer, windings are encircled around some part of core. The cylindrical coils are insulated from each other with the help of paper or cloth and encompass high mechanical strength. Low voltage windings are arranged in a specific way to provide quick insulation with the laminated core of steel. A core type transformer is shown in the figure given below. L.V and H.V are described as Low voltage windings and High voltage windings respectively.

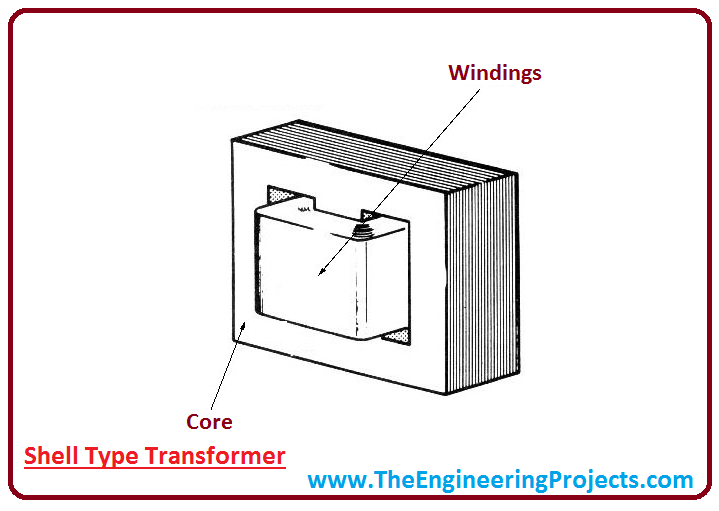

Shell Type Transformer

Shell type transformer comes with a steel core that covers some part of the coil windings. The coils in this transformer are also form-wound and are arranged in different layers that are insulated from each other. Such type of transformer comes in two shapes i.e. rectangular type or distributed type. It is like a disc arranged with insulated spaces, providing a horizontal cooling. Both, rectangular and distributed types of shell transformer are given in the figures below. In order to provide compact look and minimum movement, this transformer comes with a rigid bracing that combines the whole transformer at one place. Main purpose of bracing is to control vibration and provide minimum noise during operation. Both, shell type and core type transformers, encompass same characteristics but they are different with respect to cost. Shell type transformer is high in demand due to high voltage and the construction of its design. Things that are taken into consideration before buying the transformer include, heat distribution, cooling process, weight, voltage rating and kilo-watt ampere rating.

5. Energy Losses in Transformers

Transformers are used for the transformation of electrical energy. The coils used in the transformer are entitled to many energy losses. Some of them are given below:Heat Loss

Heat loss is a common factor in transformer. Some form of energy is used to reduce the resistance in the transformer in order to provide steady flow of electrical energy from one coil to another. When it escapes from coils of the transformer, this energy is converted into heat which erupts the energy loss. Heat loss can be minimized by using the good conducting material in the coil or by using wires of high cross sectional area. Eddy current also pertains to heat loss. When primary coil is connected to the electrical power, it induces the alternating magnetic field in the primary coil. Same magnetic field also passes through the steel core, helps in inducing the small current in the same core which erupts heat losses. In order to overcome heat loss, steel core must be laminated perfectly. This can be achieved by placing an insulating strips in the strips of the core material. Without effecting magnetic field, these insulating strips results in reducing the eddy current.Hysteresis Loss

Hysteresis Loss also occurs due to magnetic field passing through the core material. When magnetic field passes through the core, the core becomes real magnet with separate north and South Pole. As the magnetic field changes its direction it also allows to magnetize the core material in another direction. Energy loss happens when core is magnetized in one direction and resists the core to magnetize in another direction. Surplus energy is required to magnetize the core material in other direction. Only way to minimize the hysteresis loss is to use the core material that is made up of good magnetizing material such as iron, which can be re-magnetized easily than other materials.6. Applications of Transformer:

After reading the whole article, you have got the clear idea what is the basic purpose of electrical transformer. It can be used in our homes, apartments, buildings and electrical appliances i.e. where electrical power is required according to our needs and requirements. Following are the some applications of transformer:- It can be used to alternate the amount of voltage and current. When current increases, voltage decrease and when voltage increases, then current decreases i.e. P = V * I

- Value of reluctance, capacitance and resistance can be controlled by the help of transformer.

- It finds many applications when it prohibits the flow of DC current from one circuit to another.

- Transformer is also used as an impedance device where same amount of voltage is required to the output as implied to the input. Hence, it also allows the two circuit be electrically isolated.